TM 1-4220-250-12&P

4.8.4

Repair Inflation Assembly.

This task covers: a Repair

b. Remove

c. Install

INITIAL SET UP

Tools/Equipment

Valve, Inflation,

Aircraft General Mechanic Tool Kit

Type II

MIL-I-23145

Torque Wrench 0-1 50 inch lbs.

Abrasive Mat

(D5)

Corrosion Preventive

Materials/Parts

Compound (Aimguard) Type I (D6)

Thread, Nylon

(D19)

Lubricant, Silicone

(D16)

Kit, Gasket

105AS100-5

1.

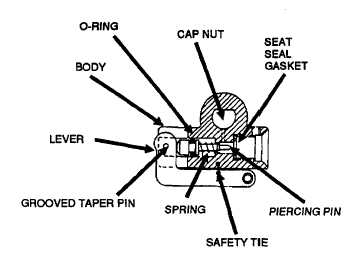

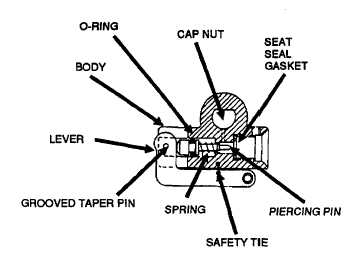

Repair of C02 Inflation Valve. To repair theC02

inflation valve, proceed as follows. See Figures 4-2

and 4-3.

a.

Remove C02 cylinder from valve assembly by

removing

and

discarding

ordnance

tape.

Ensure set screw is loose so as not to damage

C02 cylinder threads.

NOTE

Do not descard set screw

b.

Remove C02 cylinder from valve. Remove

inflator cap nut and inflation valve from the raft.

Discard the two gaskets on the valve stem.

Figure

4-2.

CO2

Inflation

Assembly.

c.

Remove grooved taper pin (retaining lever)

from inflation valve, using awl and mallet. See

Figure 4-2.

d.

Remove lever, spring, and piercing pin.

e.

If spring is broken or corroded, replace entire

valve, in accordance with paragraph 4.6.2.

f.

If piercing pin or actuating lever is corroded,

remove corrosion with the 240 grit emery cloth

(D5). Do not damage 0-ring on piercing pin.

Wipe off any dirt or moisture from actuating

lever and apply a thin coat of corrosion

preventive compound (D6) and allow to dry.

g.

Clean residue from actuating lever on piercing

pin. Lightly coat base of piercing pin with

silicone lubricant (D16).

h.

Reassemble

inflation

valve

and

operate

actuating lever three or four times. Ensure that

lever and piercing pin move freely.

i.

If piercing pin and lever do not move freely,

replace entire valve, in accordance with

paragraph 4.6.2.

GO NEXT PAGE

4-20