TM 10-3530-207-14

4-49. BUTTON SEWING MACHINE MAINTENANCE ADJUSTMENT PROCEDURES - continued.

b.

To adjust spring tension of stop motion shaft.

NOTE

Not enough tension will not let the stop brake go down and lock. Too much tension will stop the

pulley and rotation prematurely.

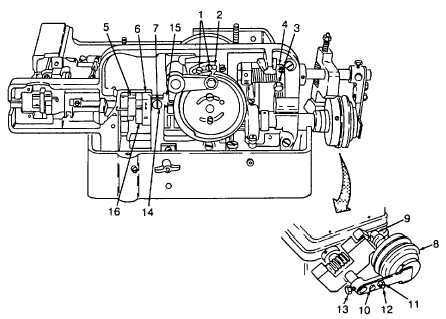

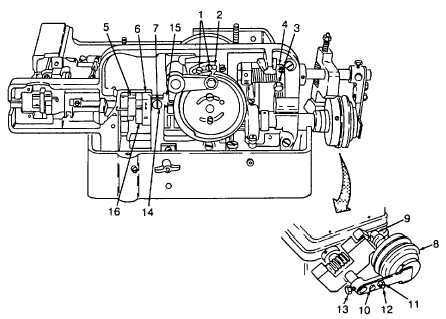

Loosen hexagon screw (3) and by means of screw (3) turn collar (4) downward for greater

tension, or upward for less tension, then securely tighten screw (3).

c.

To time the looper shaft crank and the looper driving shaft crank.

(1)

Cranks (5 and 6) must be set with the arrow on the rim of each in exact alignment with the arrow

on the machine casting at (7) when the machine is in its stopped or locked position.

(2)

To align these cranks, loosen clamping screw (14) which holds the shaft bushing (15) In the

machine bed. Turn this bushing (which is eccentric) upward toward the bed of the machine. This

will unmesh the gears and permit turning the cranks to required position. After the arrows on

these cranks are aligned with the arrow at (7), turn bushing (15) downward to again mesh the

gears, then tighten clamping screw (14).

(3)

Looper shaft link (16), which connects cranks (5 and 6) should be attached so that the large crank

(6) will PULL the looper shaft link (16). If it is attached so that it is pushed by crank (6), the

machine will not function properly.

4-109