TM 10-3530-207-14

2-11. OPERATING PROCEDURES FOR CLOTHING SEWING MACHINE - continued.

a.

Selecting Needle - continued.

(4) Needle selection is based on the following:

16 x 87, Size 16

Describes the gage and eye size of the needle.

Describes the length of needle and type of point.

Describes the needle shaft length.

WARNING

Be sure that power is turned off.

b.

Installing the Needle.

NOTE

Never use a bent needle or one with the point blunted or turned.

(1) Select a good needle of the proper size as explained in paragraph 2-lla. Set the needle with the

long groove to the left.

CAUTION

Always rotate the machine hand pulley wheel towards you. Timing the hand wheel away from

you will break or bend needles or damage bobbin case or oscillating shuttle.

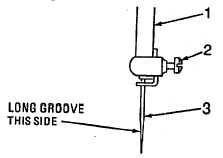

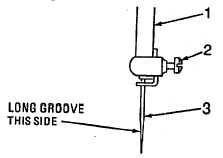

(2) To set needle (3), turn the hand wheel toward you until needle bar (1) moves up to its

highest point.

(3) Loosen needle clamp screw (2), put the shank of needle (3) up into the clamp as far as it

will go, and turn the long groove of needle (3) so that it faces to the left and is directly in

line with the arm of the machine.

(4) Tighten needle clamp screw (2). If screw (2) is too loose, needle (3) will turn or slip.

2-59