TM 10-3530-207-14

2-11. OPERATING PROCEDURES FOR CLOTHING SEWING MACHINE - continued.

i.

Operating the Clothing Sewing Machine - continued.

(4) To remove material from the machine proceed as follows:

(a) Release the foot treadle to stop the machine.

(b) Hand-turn the pulley wheel toward you until the needle bar is at its highest point and raise the

presser foot.

(c) Draw the material straight behind the presser foot, and break or cut the needle and bobbin

threads so that about four inches will remain under and behind the presser foot.

j.

Adjusting Tension on Bobbin and Needle Threads.

(1) Proper tension locks the bobbin and needle threads in the center of the material. If needle thread

tension is too tight, or if bobbin tension is too loose, the needle thread will pull to the upper

surface of the material. If bobbin thread tension is too tight, or if needle thread is too loose, the

bobbin thread will pull to the underside of the material. If both threads are too tight, the material

will be puckered and drawn together by the stitches and the threads will break. Adjust the

tensions as follows:

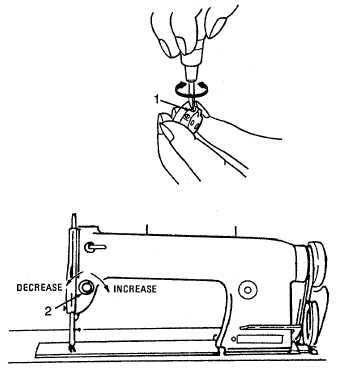

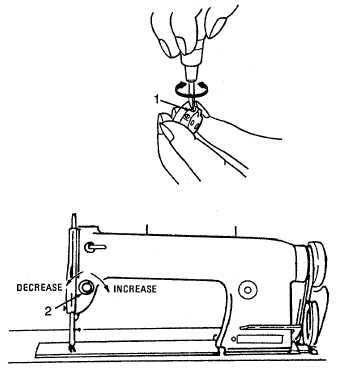

(2) Remove the bobbin case (paragraph 2-1 lid). Adjust the bobbin thread tension with the adjusting

screw (1) Turn screw (1) clockwise to increase the tension and counterclockwise to decrease

tension.

(3) Lower the presser foot onto the feed dog to close the tension disks. Adjust the needle thread

tension with the tension thumb nut (2). Turn thumb nut (2) clockwise to increase tension and

counterclockwise to decrease tension.

2-68