Item

Interval

No.

M

S

A

Item to be inspected

Procedures

TM 10-3510-209-24

Table 2-1. Unit Preventive Maintenance Checks and Services (Continued)

M-Monthly

S-Semiannually

A-Annually

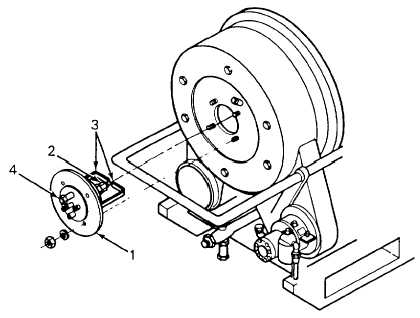

5

WATER HEATER BURNER HEAD AND NOZZLE ASSEMBLY

a.

Inspect burner head (1) for cracks, breaks, and damage.

b.

Inspect nozzle assembly (2) for carbon deposits, damage, and

loose mounting.

c.

Check electrodes (3) for carbon deposits and loose

connections.

d.

Look through sight glass (4) during operation and check for

proper spark.

e.

With unit operating, check for proper operation.

f.

Check for proper temperature indication. Refer to FM 10-280.

g.

Check gasket on control box for proper sealing.

2-20