TM 10-3510-226-10

0003 00

OPERATOR MAINTENANCE

CONTAINERIZED BATCH LAUNDRY (CBL)

NSN 3510-01-527-2209

NSN 3510-01-527-2210

THEORY OF OPERATION

General

The Laundry, Batch, Containerized (CBL) operates as a standalone system, and is comprised of two

washers, two dryers, an internal water boiler, a water reuse filtration system, utility connectors (source

water, graywater, and electrical), circuit breaker panels to distribute power and provide circuit protection,

and a Programmable Logic Control (PLC) which provides centralized control of all components outside of

the washers and dryers. The system is a manned station designed to process 150 to 200 pounds of

laundry per hour including batches of uniforms and hospital linens.

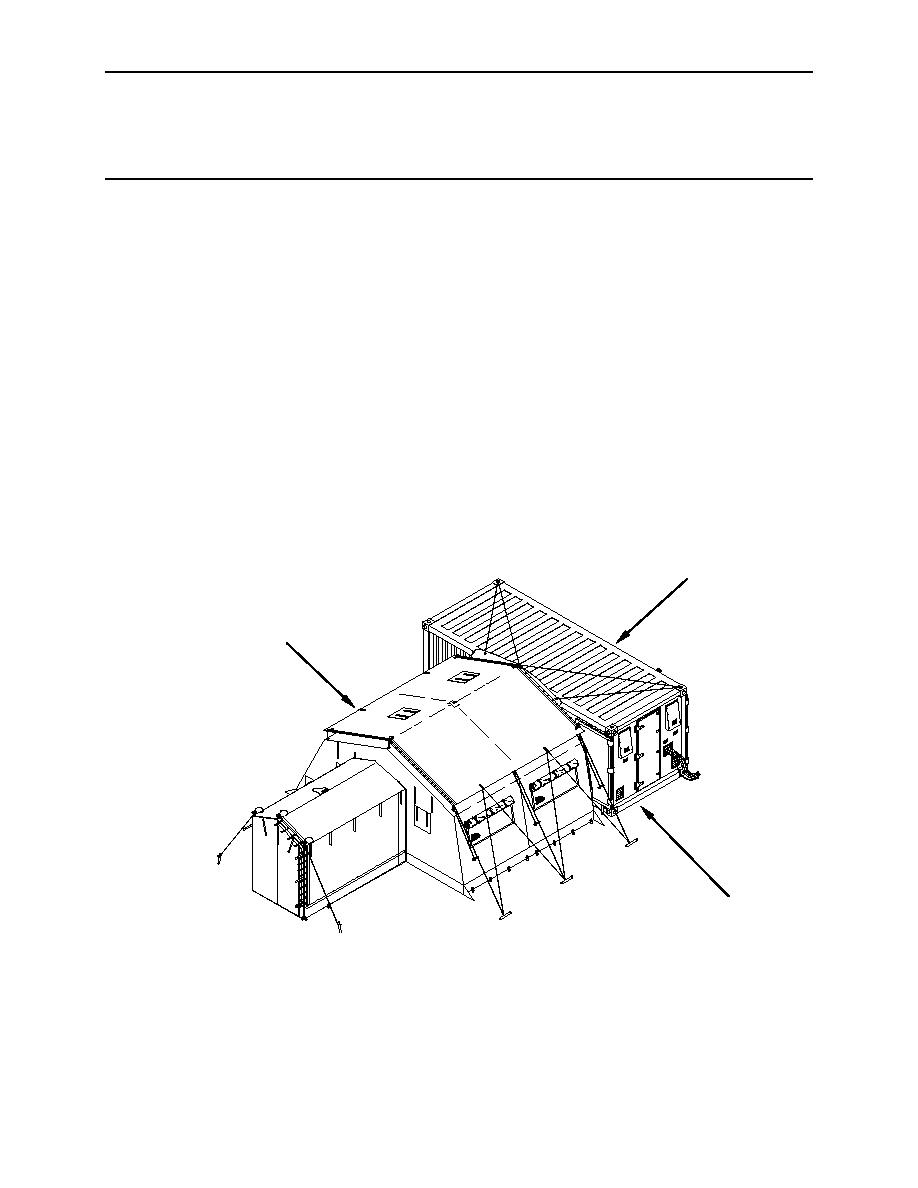

CBL

The CBL is housed in a modified 8-ft x 8-ft x 20-ft ISO cargo container (Figure 1, Item 1). Two 50-pound

capacity automatic washers and two 75-pound capacity automatic electric dryers are housed within the

CBL container. Main access to the CBL is through double entrance doors, which are opened before

attachment of the TEMPER (Figure 1, Item 2) and bootwall. Service entry doors (Figure 1, Item 3) at

each end of the CBL allow access to the back of both the washers and dryers.

TEMPER

The 16-ft x 20-ft TEMPER (Figure 1, Item 2) is used as a work station for accepting, sorting, and

distributing laundry. The TEMPER attaches to the CBL container (Figure 1, Item 1) by means of a

modified endwall. The TEMPER is equipped with lighting and utility receptacles to provide the necessary

illumination and electrical service for the workspace. The TEMPER lighting is equipped with blue sleeves

for operation in blackout condition.

1

2

3

Figure 1. CBL.