TM 10-3510-226-23

0003 00

THEORY OF OPERATION-CONTINUED

Water Reuse System

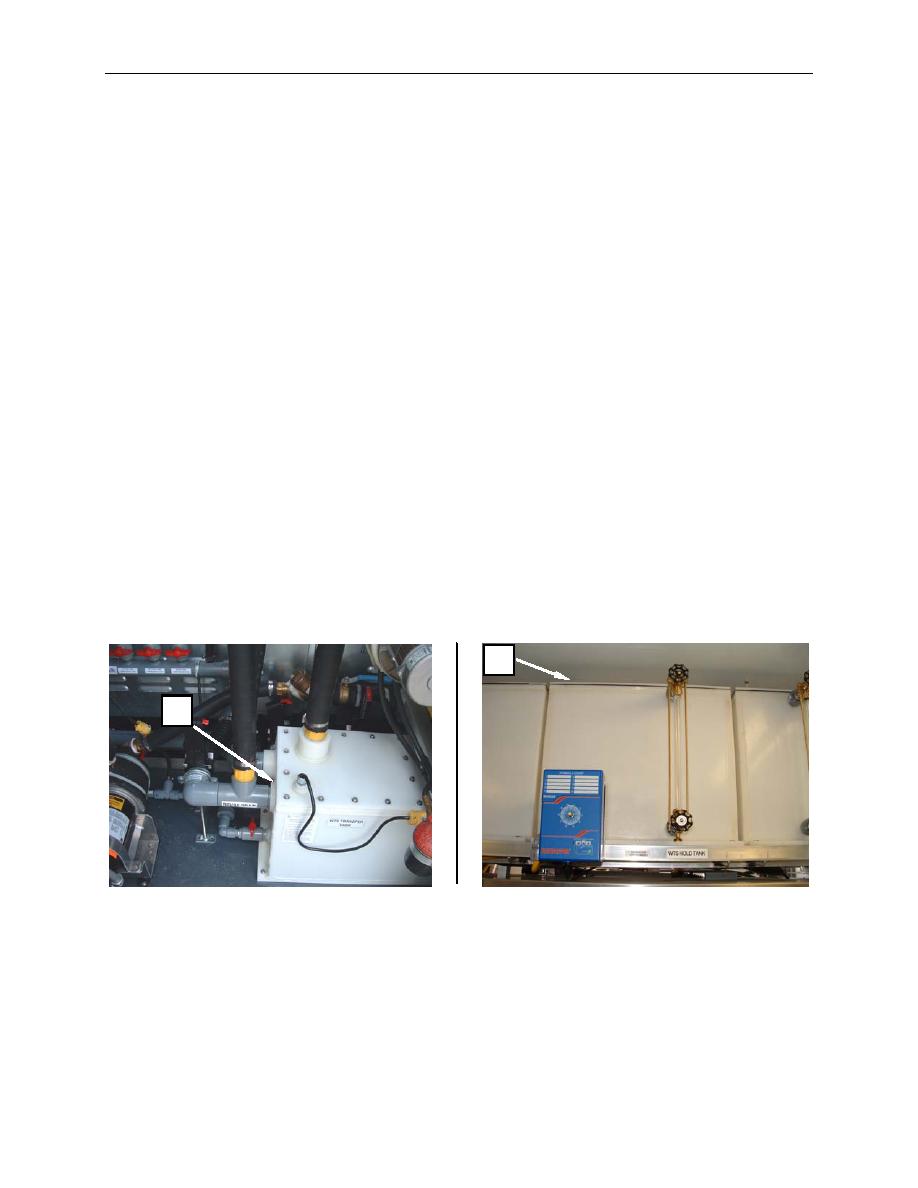

The CBL utilizes a water reuse system that filters wash water from the washers and stores it in a reuse

tank for use in subsequent wash loads. Wash water from the washer is discharged from a reuse drain into

the Water Treatment System (WTS) transfer tank (Figure 4, Item 1) located behind the washers. When

the WTS transfer tank is full, the untreated wash water is pumped up to a WTS holding tank (Figure 4,

Item 2) located over the washers. Pump P3 (Figure 5, Item 3) takes water from the WTS hold tank and

sends it through the F-1 (Figure 5, Item 4) and F-2 (Figure 5, Item 5) filters to remove gross impurities.

Water is then routed to the nanofiltration feed tank (Figure 5, Item 6) for collection. Water from the

nanofilter feed tank is fed into Pump P-4 (Figure 5, Item 7) and through a series of three nanofiltration

vessels (Figure 5, Item 8) that remove all remaining impurities and bacteriological products. Water then

passes through carbon filter F-3 (Figure 5, Item 9) and is stored in the reuse tank (Figure 5, Item 10) for

later use.

Two additional modes of operation are available:

Minimum Reuse

In Minimum Reuse mode, wash water from the washers is diverted directly to the reuse tank, bypassing

the filtration system. Minimum reuse requires the operation of valves V-15 and V-16 in order to be

employed.

The minimum reuse mode is not recommended unless the filtration system is inoperable and water

conservation is critical.

No Reuse

The water reuse system may be bypassed entirely by simply selecting the appropriate cycles on the

washers. All water is then discharged directly to the waste tank and pumped out as graywater. No reuse

is recommended if the filtration system is inoperable.

2

1

Figure 4. Water Reuse System.

0003 00-4