TM 10-7360-226-13&P

0002 00

CONTAINERIZED KITCHEN (WITH TRAILER)

EQUIPMENT DESCRIPTION AND DATA

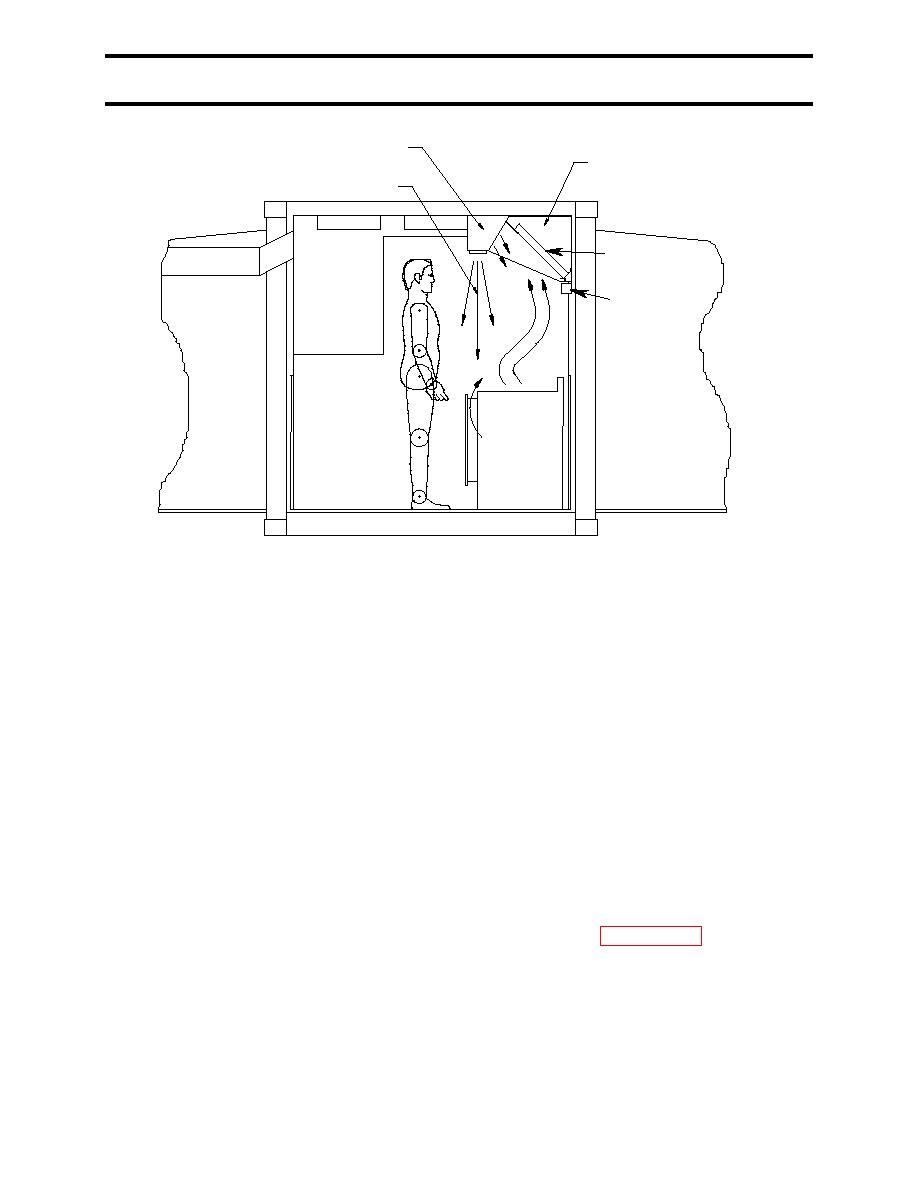

DUCT FROM MAKEUP AIR FAN

DUCT TO EXHAUST FAN

AIR CURTAIN

GREASE

FILTERS

GREASE CUP

Figure 14. Cook Center Exhaust Hood.

The exhaust hood includes removable, washable, aluminum baffle-type grease filters. A tilted

grease trough beneath the filters collects grease and directs it to a removable collection cup.

Air supply and exhaust are provided by two identical, variable-speed fans located in the

mechanical room. Under normal conditions, the fans operate at approximately 60 to 75%

capacity. The remaining capacity provides for unusual conditions when large amounts of smoke

or steam must be exhausted from the kitchen.

Environmental Control System - ECU

The Environmental Control System consists of two dual-stage air conditioners located in the

mechanical room, three heating elements located in the air conditioner evaporator discharge

plenum, fixed and removable ductwork, filters, and an Environmental Control Unit (ECU).

Components of the ECU include a wall-mounted mode selector switch in the food preparation

area and a controller mounted on the back wall inside the mechanical room.

Each air conditioner has a rated cooling capacity of 24,000 BTU/hr, and contains two

independent compressors. Under the control of the ECU, the four compressors operate

independently to provide staged cooling capacities of 12,000 BTU/hr, 24,000 BTU/hr, 36,000

BTU/hr, and 48,000 BTU/hr. ECU operation is described in detail in WP 0003 00.

When the heaters are operating, one air conditioner fan runs to circulate the heated air. The

heaters are designed to provide only limited control of kitchen temperature without overloading

Change 2

0002 00-13