NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

g. Relays. Deposits of varnish on the armature,

c. Sealing Compound, MIL-PRF-81733 (Volume IV

pivots, or similar components will cause the relays to

or V, Chapter 2), can be used to seal gaps, seams, and

bind. The whole relay should be carefully masked until

faying surfaces with temperatures up to 250F (121C).

after spraying has been completed. A brush should be

This material is applied by brush.

used to coat the coils and leads after the masking has

been removed. Relays with palladium-tipped contacts

d. C o n f o r m a l Coating. For information on

should be removed before application of varnish.

procedures and equipment used to apply conformal

coatings, refer to NAVAIR 01-1A-23 (Navy) and TO

h. Meters. Since meters are easily damaged by a

00-25-234 (Air Force).

the varnish spray treatment, all meters must be checked

for accuracy before treatment. Some meters may be

CAUTION

affected by heat. In other instances, meter magnets

may be affected by magnetic fields that exist around

A large number of RTV silicone sealants

drying equipment. Refer to the applicable service

contain an acetic acid curing agent. These

directives for instructions on varnish spray treatment of

sealants, in contact with metal, result in rapid

meters. If guidance is not available, do not apply varnish.

corrosion. RTV sealants that contain acetic

acid are not authorized for use on electronic or

5-5. SEALANTS FOR AVIONICS. Sealants are

electrical circuit. They may be identified in

another type of protective film used in avionic

most cases by a vinegar odor while in a liquid

equipment. Sealants are usually liquid or paste, which

or curing state.

solidify after application. They form a flexible seal,

preventing moisture intrusion at mechanical joints,

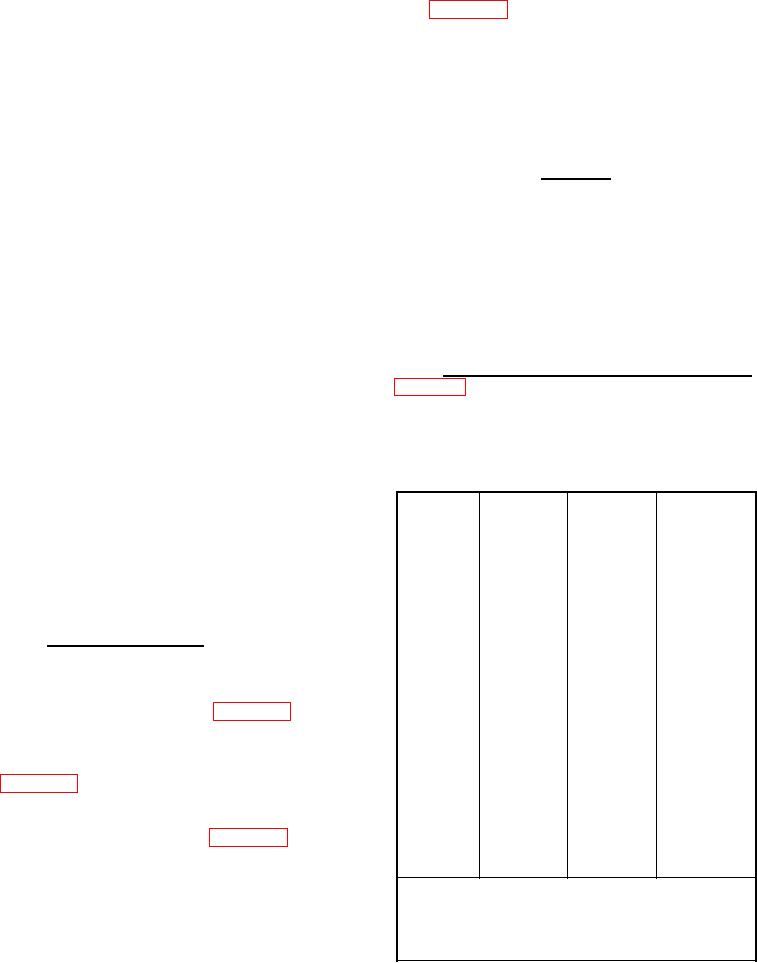

5-5.2. SEALANT CONTAINING ACETIC ACIDS.

spot-welds, and threaded closures. In addition, sealants

Table 5-1 lists some of the RTV silicone sealants

prevent entry of corrosive environments to faying

considered corrosive. These sealants shall not be

surfaces, fastener areas, exposed landing gears

used in avionic equipment.

switches, and other metal-encased avionic equipment.

They function principally as waterproof barriers. It is

Corrosive Silicone Sealants,

therefore very important that damaged sealants be

Adhesives, and Coatings

repaired as soon as possible.

RTV 102

RTV 192

RTV 999

RTV 92-055

NOTE

RTV 103

RTV 198

RTV 1890

RTV 94-002

RTV 106

RTV 236

RTV 3144

RTV 94-003

For application procedures of Sealing

RTV 108

RTV 730

RTV 20-046

RTV 94-009

Compound, MIL-PRF-81733, refer to Volume

II of this manual.

RTV 109

RTV 731

RTV 20-078

RTV 94-034

RTV 112

RTV 732

RTV 30-079

RTV 96-005

5-5.1. TYPES OF SEALANTS. The following sealants

shall be used on avionic equipment:

RTV 116

RTV 733

RTV 30-121

RTV 96-080

RTV 118

RTV 734

RTV 4-2817

RTV 96-081

a. Sealing Compound, Low Temperature Curing,

MIL-S-83318 (Volume IV or V, Chapter 2), is a quick

RTV 140

RTV 736

RTV 90-092

RTV Q3-6069

cure sealant used for sealing gaps and depressions on

RTV 142

RTV 780

RTV 92-005

RTV Q3-6090

areas during extreme cold activities. Apply with Brush,

RTV 154

RTV 781

RTV 92-007

RTV Q4-2817

Typewriter, A-A-3077 Style T (Volume IV or V,

RTV 156

RTV 784

RTV 92-009

RTV 92-010

RTV 157

RTV 785

RTV 92-018

SCS 101

b. Adhesive-Sealant, Silicone, RTV, Noncorrosive,

MIL-A-46146 (Volume IV or V, Chapter 2), is used for

RTV 158

RTV 786

RTV 92-024

RTV 159

sealing avionic equipment in areas where temperatures

RTV 891

RTV 92-048

are between 250F (121C) to 600F (315C). It is

NOTE

used for encapsulating and sealing of electrical and

RTV 730 is a high temperature (550 to 600 F) corrosive sealant

electronic components. This material has good

that may be required to seal engine compartment electrical

resistance to oxidation, weathering, and water.

connectors. RTV 730 shall be used only when specified by the

cognizant engineering authority.

5-7/(5-8 Blank)