01 March 2005

NAVAIR 01-1A-509-3

TM 1-1500-344-23-3

TO 1-1-689-3

Chapter 3), or Sealant Gun (Volume IV or V, Chapter 3)

with nozzle (Volume IV or V, Chapter 3) and retainer

cartridge. Mix sealants in accordance with manufacturer

instructions and form a fillet of sealing compound

around outside edge of antenna base to form a water

tight seal.

j. Check electrical resistance as specified by

applicable aircraft TO/MIM/TM. If no other instructions

apply, use paragraph 6-3.1.12.

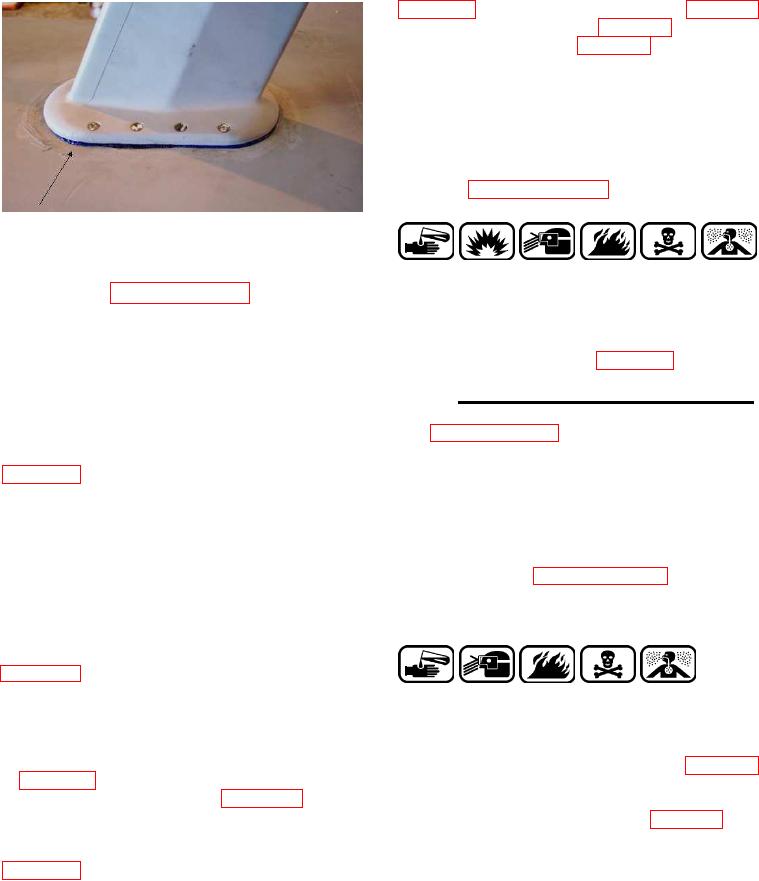

Figure 6-6. Typical Gel Squeeze-Out

Around Perimeter of Antenna

Compound, Corrosion Preventive

8

f. P e r f o r m the electrical resistance test in

MIL-PRF-16173

accordance with paragraph 6-3.1.12. after the antenna

is fully installed or the ground installation is assembled.

k. Cover antenna fastener heads with a thin film of

The test shall take place prior to applying outer edge

MIL-PRF-16173 Grade 4, Corrosion Preventive

sealant, if applicable.

Compound (Volume IV or V, Chapter 2).

g. Inspect antenna mounting fasteners to ensure

6-3.1.4. Alternate Method for Rigid Antenna Mounting.

that the countersink taper area of each fastener head

This method may be used when conductive gaskets

is clean and free of corrosion. If not, use new fasteners.

(see paragraph 6-3.1.3.) are not authorized or available.

Apply thin film of Water Displacing Corrosion Preventive

The following installation procedures, including

Compound, MIL-C-81309 Type III (Volume IV or V,

application of corrosion prevention measures and

Chapter 2), (Air Force can use MIL-L-87177 Grade B

attachment of the antenna to the airframe structure,

as an alternate) to fastener threads prior to installation.

are typical and may be used for mast-type antennas

(blade, spike, whip base, or long wire mast base).

h. Remove release film from the "aircraft side" of

the gasket. Pre-position at least two fasteners through

a. Prepare aircraft skin and antenna mounting area

the antenna base and gasket. Align fasteners at correct

in accordance with paragraph 6-3.1.2.a. through g.

locations on the aircraft surface. Hand tighten each

Remove anodized coating from countersink areas on

fastener one or two turns to hold the antenna in place

new antennas.

on the aircraft. Install remaining fasteners and secure

antenna to aircraft by torquing each fastener in

accordance with specific aircraft TO/MIM/TM.

Figure 6-6 shows an antenna and typical gel

squeeze-out around the perimeter of the antenna

Coating, Chemical Conversion

10

base, after the antenna has been installed.

MIL-DTL-81706

i. For maximum corrosion protection, apply an

b. A p p l y Chemical Conversion Coating,

outer edge seal, Thixoflex Gray Sealant (Volume IV or

MIL-DTL-81706 Class 3 (Volume IV or V, Chapter 2)

V, Chapter 2), with 50 cc Injectable Sealant Application

with Alodine Touch 'n Prep Pen as preferred method,

Dispenser (Volume IV or V, Chapter 3). Or, for

to bare countersink areas in accordance with the

maximum corrosion protection and resistance to aircraft

procedure described in Volume II and Chapter 5. If the

fluid attack on the gasket apply an outer edge seal,

Touch 'n Prep Pen is used, only one coat should be

SAE-AMS-3277 Fast Cure Sealant (Volume IV or V,

applied and the treated surface does not require rinsing

Chapter 2), using Spatula, A-A-277 (Volume IV or V,