NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

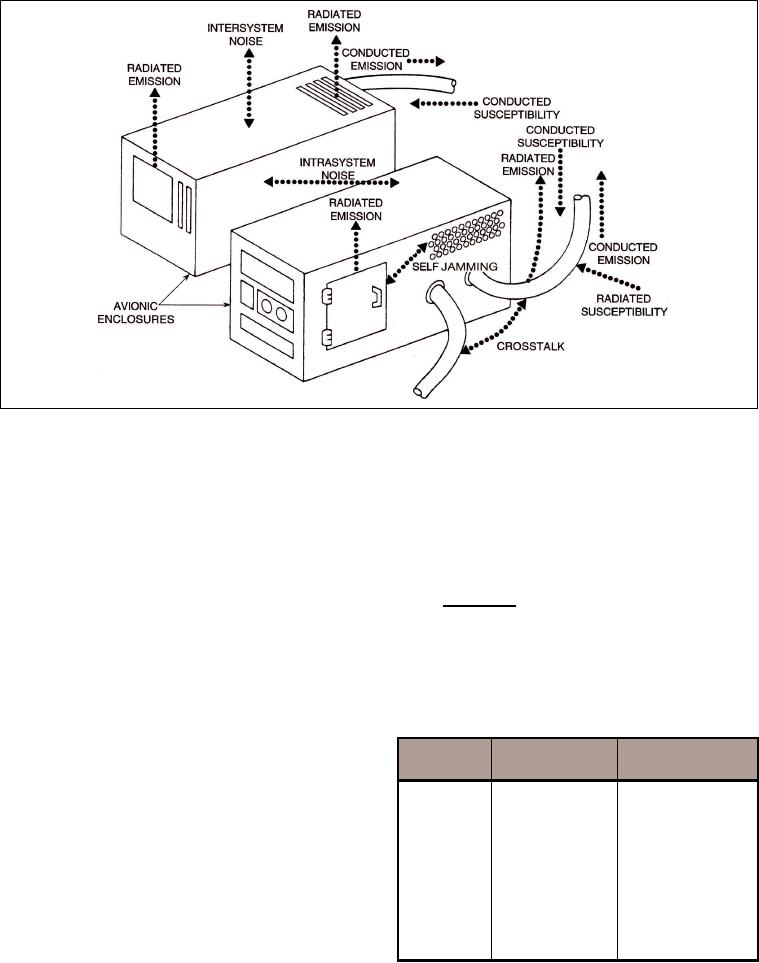

Figure 7-2. Classification of EMI Problems

a. Conductivity: Good conductivity is taken as a

g. Wear resistance: Important when the gasket is

rough, indirect measure of EMI shielding. In addition,

repeatedly compressed and depressed.

a contact resistance of 2.5 milliohms is specified

across joints for grounding and lightning strike

h. Conformability: Accommodate joint unevenness.

protection.

7-5. EFFECTS OF CORROSION.

b. Corrosion resistance of gasket material:

Properties should not change with service (e.g.

7-5.1. GENERAL. Corrosion can degrade the electrical

corrosion which produces an insulting layer of material).

and mechanical properties of a joint. The exposure of

EMI gaskets to various environmental conditions can

c. C o m p a t i b i l i t y with the mating surface:

significantly reduce its shielding effectiveness and

Electrochemical compatibility to prevent galvanic

service life. Under field service conditions, military

corrosion.

d. Good adhesive qualities: Required for electrical

Table 7-3. Materials Used in EMI Joints

contact and environmental scaling.

Enclosure

Coatings

Fillers Used in EMI

e. Chemical resistance to solvents: Properties

Gaskets

should not change with exposure to operational

Carbon

Silver

Steel

chemicals (e.g. fuel, paint stripper, hydraulic fluid).

Silver

Copper

Aluminum

Copper

Nickel

Magnesium

f. Resilience: Resistance to compression required

Beryllium/Copper

Tin

Composites

Phosphor Bronze

Cadmium

Plastic

for electrical contact and environmental scaling. Long

Monel

Aluminum (IVD)

term pressure should not cause permanent deformation

Stainless Steel

Zinc

(compression set). Normal deflection for solid

Steel

Chromate

rectangular elastomer seals range from 5 to 15%.

Nickel

Phosphate

Tin

Aluminum