TM 10-3510-208-12

(3) Position the rotary switch unit (14) on the

c. Cleaning.

bracket ( 18) and secure with screws (13), lock-

washers (12) and nuts (11).

Clean all parts in a well-ventilated area.

Avoid inhalation of solvent fumes and

(4) Install the conduit (9), connectors (8 and

prolonged exposure of skin to cleaning

10) and outlet box (7) on the generator switch box.

solvent. Wash exposed skin thoroughly.

(5) Install the junction support (6) on the

Dry cleaning solvent (Fed. Spec. P-D-680)

outlet box (7) and secure with bolts (5), lock-

washers (4) and nuts (3).

used to clean parts is potentially dangerous

(6) Install the outlet box cover (2) onto the

to personnel and property. Do not use near

open flame or excessive heat. Flash point

outlet box (7) and secure with screws (1).

of solvent is 100 to 138F. (38 to 59C).

f. Installation.

(1) Install the outlet box and generator switch

(1) Clean metal parts with cleaning solvent,

box assemblies onto the engine-generator, then

Fed. Spec. P-D-680, and dry thoroughly.

install the washer (4, fig. 4-113) and bolt (3).

(2) Clean electrical components with dry

Install the lockwashers (2) and four screws (1)

compressed airand a clean cloth.

inside the generator switch box.

a. Inspection and Repair.

(2) Reconnect all wiring to the generator

(1) Inspect all parts for damage.

switch box and outlet box assemblies.

(2) Replace all damaged parts.

(3) For external power requirements with

e. Assembly.

correct electrical connections, refer to wiring

(1) Install the snap-in blank (19, fig. 4-114) on

diagram shown in figure 1-8.

the generator switch box (20).

(2) Install the support bracket (18) in the

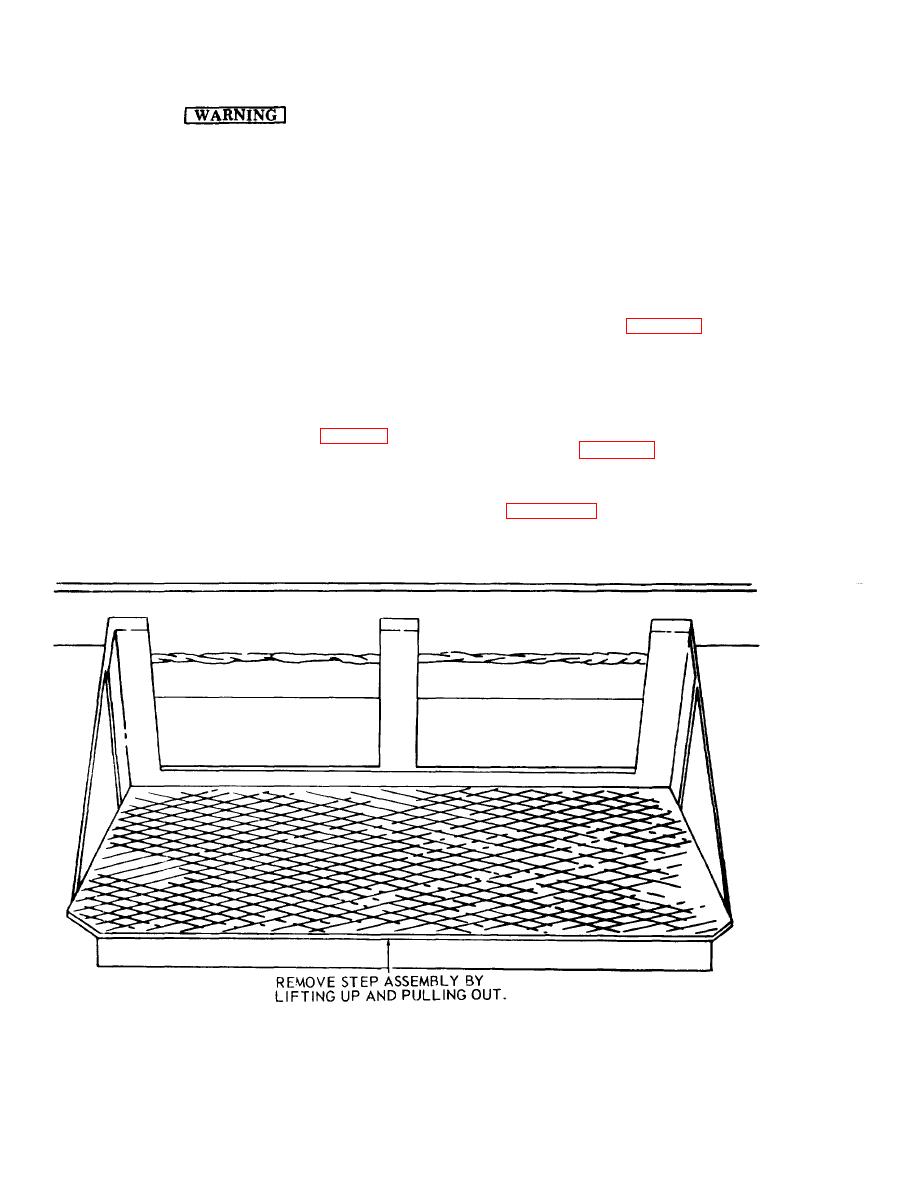

4-84. Step Assembly

generator switch box and secure with screws (17),

a. Removal For removal of the step assembly

lockwashers (16) and nuts (15).

refer to figure 4-115.

TS 10-3510-208-12/4-115

Figure 4-115. Step assembly, removal and installation.

4-162