TM 10-3510-208-34

c. Cleaning.

(1) Clean interior of the tumbler exhaust motor and

armature with dry compressed air and clean cloth.

(2) Clean bearings with high right motor oil

WARNING

Clean all parts in a well-ventilated

area. Avoid inhalation of solvent

fumes and prolonged exposure of

skin to cleaning solvent. Wash

exposed

skin

thoroughly.

Dry

cleaning solvent IF Ned. Spec. P-D-

680) used to clean parts is potentially

dangerous

to

personnel

and

property. Do not use near {>pen

flame or excessive heat. Flash point

of solvent is 100 to 138° F. (38 to 59'

C).

(3) Clean end covers with cleaning solvent Fed

Spec. P-D-680), and dry thoroughly.

d. Inspection and Repair.

(1) Inspect the covers and housing for cracks, dents.

chips and other damage.

(2) Inspect the seals for cracks, pitting and

excessive wear.

(3) Inspect the bearings for cracks, burrs and

binding.

(4) Inspect the hardware for thread damage.

(5) Replacement of all damaged parts is recom-

mended.

e. Assembly.

(1) Install grease seals (7 and 9, fig. 3-2) and ball

bearings (6 and 8) on armature I10i.

(2) Insert armature assembly items (6 thru 10) in

motor housing (5) and install covers (4 and 3) to motor

housing and secure with bolts (2) and nuts (11.

f. Installation. Refer to figure 3-1 and install the

exhaust motor and mounting plate.

3-3. Tumbler Drive Motor

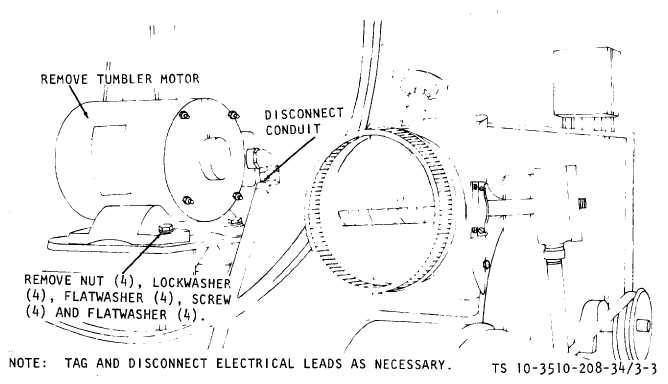

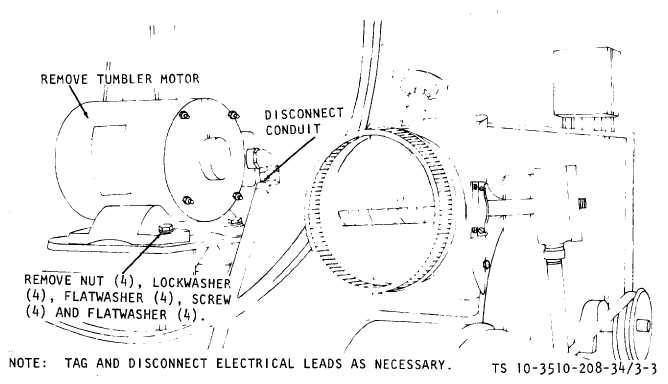

a. Removal. Refer to figure 3-3 and remove the

tumbler drive motor.

Figure 3-3. Tumbler drive motor, removal and installation.

3-4