TM 10--3510--221--10

0004 00--3/4 blank

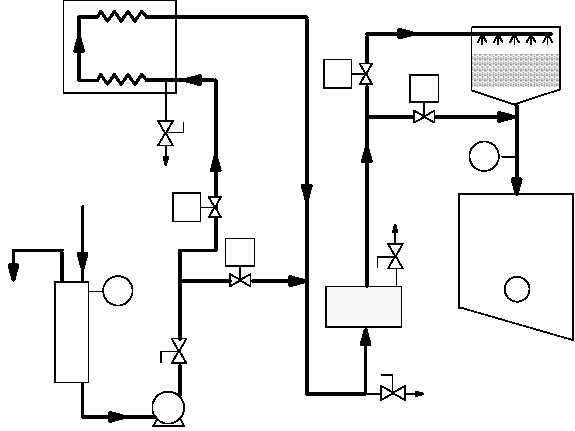

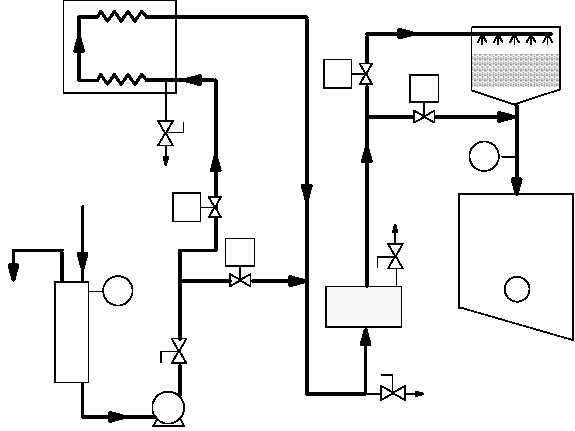

WATER RECYCLE SYSTEM THEORY

OF OPERATION -- Continued

0004 00

RINSE 2

TANK

160 GAL

DISTILLATE

PUMP

EVAPORATIVE

COOLER

CONDENSATE

FROM STILL

CONDENSER

SUBCOOLER

TE

202

LT

201

FV

200

M201

OVERFLOW

TEMPERATURE

SENSOR

LEVEL

SENSOR

STANDPIPE

COALESCER

SOLENOID

VALVE

1 OF 4

FV

202

HAND

VALVE

1 OF 8

DRAIN

HAND

VALVE

DRAIN

WASTE

DRAIN

FV

203

FV

201

HAND

VALVE

HAND

VALVE

COALESCER OPERATION

During the distilling processes some organic vapors such as light fractions of fuel or oil may codistill with the steam

exiting the top of the still. The coalescer contains a disposable element that separates the lighter organic

contamination from the heavier water. While the water recycle system is operating the coalescer drains the separated

fluid into a external waste container.

EVAPORATIVE COOLING

The evaporative cooler is used when low temperature rinse water is required during high ambient temperature

conditions. Under this condition the signal from temperature sensor (TE202), located at the rinse 2 tank, will prompt

the control system to close solenoid valve (FV202) and open solenoid valve (FV203). When these valves reposition,

water coming out of the coalescer enters the evaporative cooler. In the evaporative cooler the water is formed into

droplets. The water droplets flow through demister mesh which has ambient air passing though it. As the water flows

to the bottom of the mesh it is returned to the rinse 2 tank. When the temperature of the water returning to the rinse 2

tank is acceptable, solenoid valve (FV202) opens, and solenoid valve (FV203) closes, allowing water coming out of

the coalescer to bypass the evaporative cooler and flow directly into the rinse 2 tank.