TM 10-3510-226-23

0011 00

BOILER TROUBLESHOOTING PROCEDURES-CONTINUED

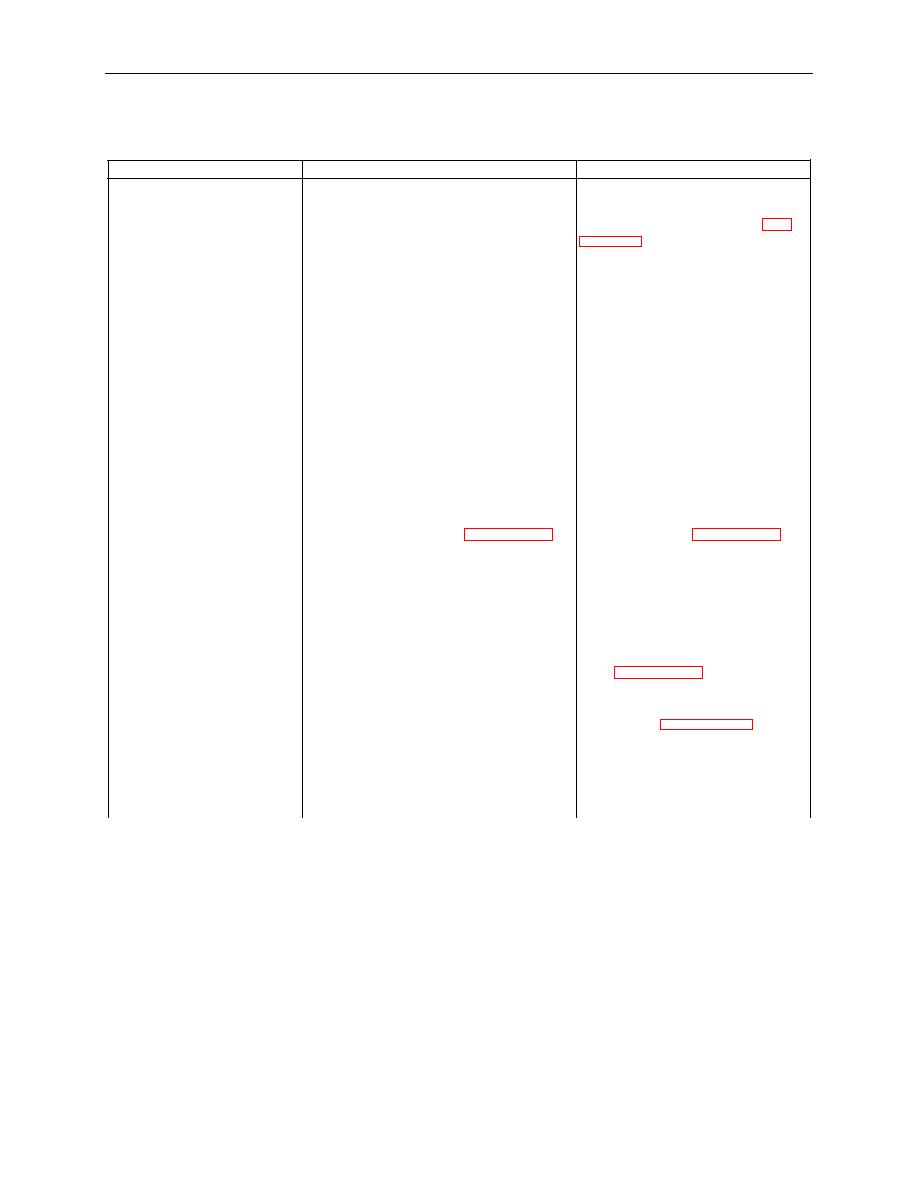

Table 1. Boiler Troubleshooting Procedures for Containerized Batch Laundry Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Provide sufficient fuel of the

Ensure fuel supply (Figure 3, Item 1)

3. Excessive fuel

correct type (JP-8, DF-1 or DF-

is of sufficient quality and quantity, and

consumption/excessive

2). Bleed fuel system IAW WP

fuel system has been bled.

smoke

bleed, inspect and replace fuel

NOTE

filter IAW 10-3510-226-10 as

necessary.

Fuel consumption will

increase if operating

Shut down CBL operation

Check for fuel leakage. Ensure hoses

without reuse.

immediately and remedy source

are connected correctly to the fuel

of leak.

adapter.

Use a screwdriver in the

Check temperature settings on the

adjustment hole (Figure 3, Item

operating thermostat (Figure 3, Item

3) to reset thermostat settings to

2).

205 oF 210 oF in the

temperature dial window (Figure

3, Item 4).

Verify operation of draft inducer fan

Replace inoperative draft

inducer fan IAW WP 0071 00.

Check burner air intake (Figure 3,

Clear burner air intake of dirt

Item 6).

and lint. Ensure damper

adjustment is tight. Check

setting.

Inspect fuel nozzle (Figure 3, Item 7).

Tighten or replace fuel nozzle

IAW WP 0069 00.

Check exhaust gas sensor (air switch)

Replace inoperative exhaust gas

(Figure 3, Item 8).

sensor IAW WP 0070 00.

If further corrective action is

required, notify direct support

maintenance.

Change 1

0011 00-5