TM 10-3530-207-14

4-49. BUTTON SEWING MACHINE MAINTENANCE ADJUSTMENT PROCEDURES - continued.

i.

To time the looper - continued.

(5)

The above setting must be made for each variation in the distance between holes in the button

as the distances between holes increase; that is, if the looper is timed for a button with holes 7/64

inch apart, it must be reset for a button with the holes farther apart.

(6)

However, if the looper is timed to handle a button with the holes 7/32 inch apart, it is not

necessary to retime the looper for every button having the same or lesser distances between the

holes.

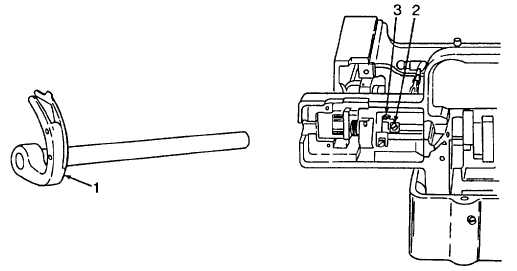

To time the needle guide.

(1)

Remove button clamp and needle plate before adjusting.

(2)

The guide (1) is generally timed so that it starts to move back (toward the right) when the needle

bar, on its upward stroke and has risen approximately 13/16 inch.

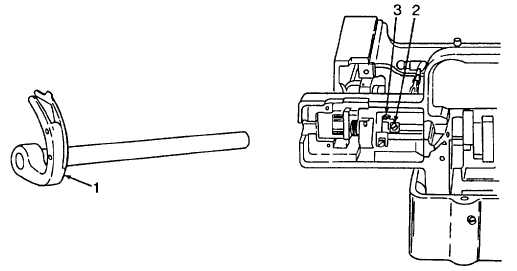

(3)

To adjust, loosen the screw (2) in the cam (3) on the looper shaft. Turn the cam (3) to the

required position, then tighten the screw (2).

(4)

Rotate machine by hand to check adjustmentper paragraph 4-49i.

NOTE

It is sometimes necessary to vary slightly the timing of the needle guide, depending upon the

nature of the material to which the button is sewn and the distance between the holes in the

button.

4-116