TM 10-3530-207-14

4-49. BUTTON SEWING MACHINE MAINTENANCE ADJUSTMENT PROCEDURES - continued.

m.

To adjust as a needle guide.

(1)

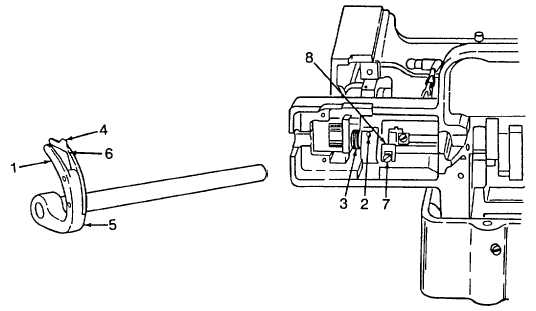

The front prong (1) is the needle guide and should be adjusted with its inside surface just clearing

the needle.

(2)

To adjust, loosen the set screw (2) which holds the needle guide shaft bushing in which the

needle guide shaft has its bearing. Move this bushing endwise in the desired direction. Then

securely tighten the set screw (2) The needle guide shaft bushing is concealed by the coil spring

(3).

n.

To adjust for thread control.

NOTE

Time the machine before making the following adjustment per paragraph 4-49i.

(1)

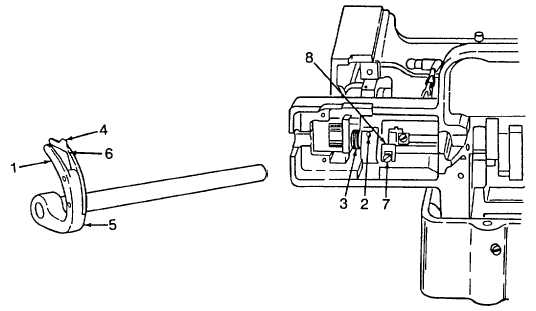

The needle guide thread finger (4) which forms the rear prong of the guide (5), is the thread controlling

portion. It should be adjusted so that the point of the needle, on its downward stroke, clears the inside

of the thread finger at (6) by about 1/32 inch when the needle bar is on its left hand vibration, or throw

(2)

To adjust, loosen clamping screw (7) in the needle guide oscillating crank (8). Turn the needle guide

(5) to the required position and securely tighten the screw (7).

NOTE

The above adjustment, to provide a clearance of about 1/32 inch, must be made for each

variation in the distance between the holes in the button.

4-118