TM 10-3530-207-14

4-49. BUTTON SEWING MACHINE MAINTENANCE ADJUSTMENT PROCEDURES - continued.

k.

To time the button clamp feed cam.

(1)

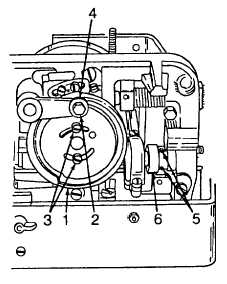

The button clamp feed cam (1) should be timed so that the arrow on its rim is in alignment with

the arrow on the button clamp carrier driving arm (2) when the machine is in its stopped or locked

position.

(2)

To adjust, loosen the two screws (3) and set cam (1) so that the arrows are in alignment with

each other at (4) then tighten the screws (3).

l.

To time the automatic tension.

(1)

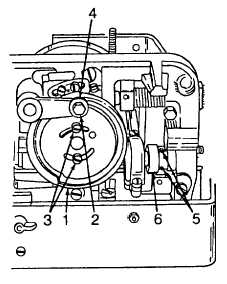

Depending upon the type of button and material being sewn, the needle bar should move from

about 3/8 inch to about 5/8 inch to complete its upward stroke after the automatic tension has

released the thread.

NOTE

Note that this cam also serves as an end thrust collar for the main shaft; therefore, make certain

that it is in contact with the shaft bearing in the machine bed, then securely tighten the two

screws (5)

(2)

To adjust, loosen the two screws (5) and turn the cam (6) to the position required to get the 3/8"

to 5/8" movement.

4-117