TM 9-1005-237-23&P

3-2. M7 BLADE ASSEMBLY-MAINTENANCE INSTRUCTIONS.

THIS TASK COVERS:

b. Inspection/repair

INITIAL SETUP

Tools and Special Tools

Small arms repairman tool set (app B)

Small arms field maintenance tool kit

(app B)

Materials/Parts

Abrasive cloth (item 4, app D)

Brush (item 2, app D)

CLP (item 3, app D)

Dry cleaning solvent (item 5, app D)

LSA (item 10, app D)

Rubber gloves (item 7, app D)

Solid film lubricant (item 8, app D)

Wash pan (item 11, app D)

Wiping rag (item 12, app D)

INSPECTION/REPAIR

References

Appendix B

Appendix C

Appendix D

paragraph 2-9.A. Disassembly,

Inspection/repair, Clean/

lubricate and Reassembly of

M6 and M7 Bayonet-knives

Equipment Conditions

paragraph 2-9.A. grips are

removed from M7 Bayonet-knife

1. Check blade for nicks on the cutting edge. Nicks up to 3/16-in. (0.48 cm)

can be removed by grinding. Ground areas shall be blended with adjacent

surfaces. Blades with deeper nicks should be replaced.

2. Repair broken point on blade by grinding and/or stoning.

After pointing,

the length of the blade (measured from the front face of the guard to the tip

of the blade) must be at least 6-1/8 in. (15.56 cm). If less than 6 1/8 inch,

replace bayonet.

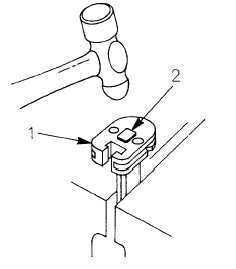

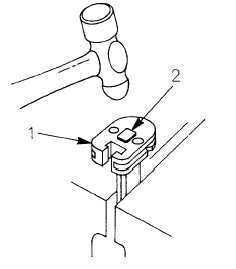

3. Inspect plate area (1) of blade for looseness. Tighten if necessary by plac-

ing blade in vise and stake or peen end of shank (2) over plate. Make sure that

sufficient clearance remains to permit retention of the bayonet to the rifle.

3-4