TM 9-4940-444-14 & P

A10C-1

1274

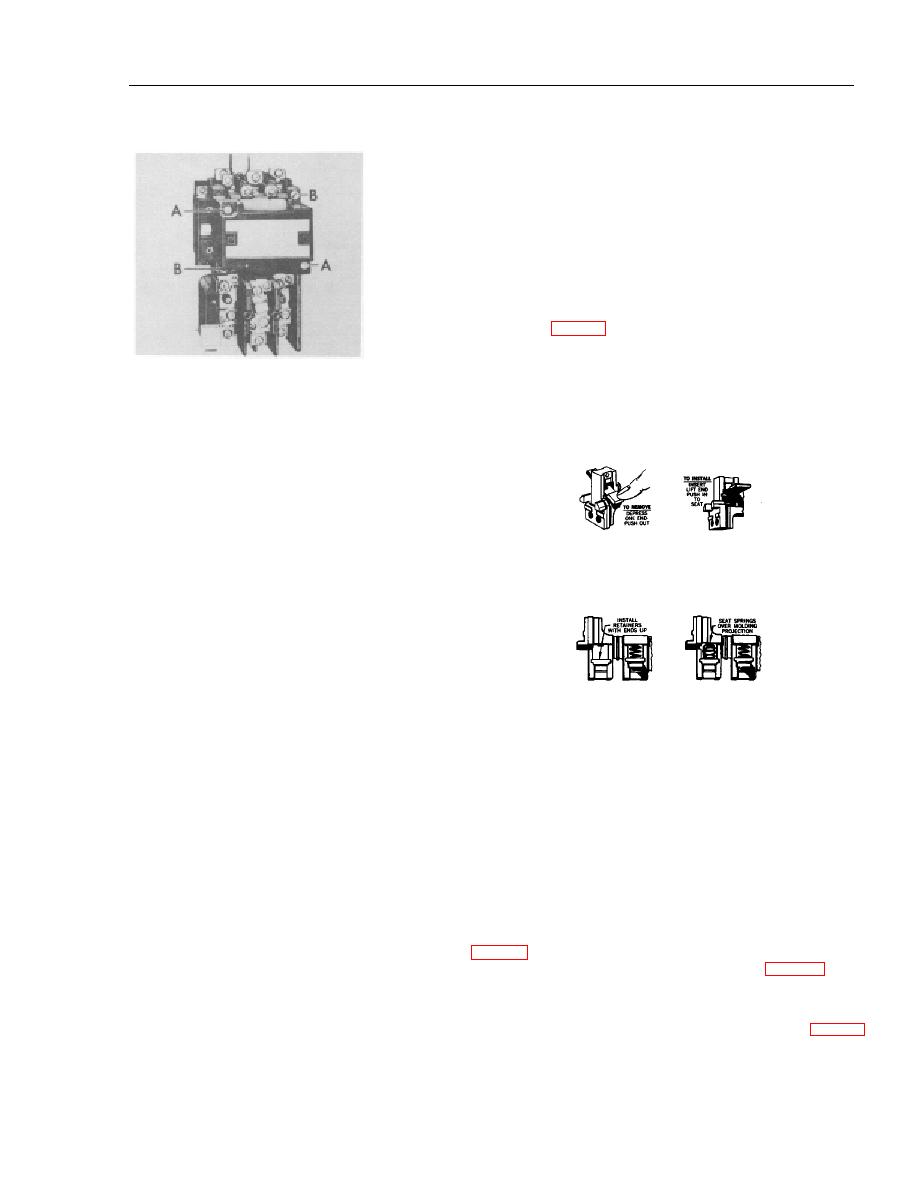

RENEWAL PARTS AND INSTRUCTION PUBLICATION FOR NEMA SIZE "1"

3 POLE STARTER WITH STANDARD TRIP EUTECTIC OVERLOAD RELAY

NOTE The power unit item 1 consists of a factory assembly of

all the magnetic parts, movable contacts, and their carrier

assembly. This unit usually permits immediate restoration

to service of a device which may have become Inoperative.

Unfasten the two gold colored Hex. Head screws "B",

pull out the power unit, plug-in the new and retighten the

screws "B". A set of stationary contacts is included with the

power unit, It is advisable to install these stationary contacts

at the same time, particularly if visual inspection indicates

that both the movable and stationary contacts need

replacement. Specify coil by suffix letter selected from coil

table on page 55.

RENEWAL OF POWER CONTACTS

The power contacts when used within their rating will

Typical Starter Three Pole with Two Circuit Electrical Interlock

provide long trouble free life. They should not be filed or

INTRODUCTION

dressed.

This publication is designed to simplify inspection and

1. Remove the power unit assembly by loosening the two gold

maintenance. It features...

colored slotted hex head screws "B" and pull the power unit

1. A publication number keyed to the ordering number of the

straight out.

device...to simplify filing and fact finding.

MOVABLE CONTACTS

2. A nameplate inscription keyed to the specific renewal parts

publication...to eliminate cross referencing.

3. An exploded view for easy, positive identification of parts

with illustrated steps on "how to assemble and

disassemble"...to conserve time and eliminate guesswork.

4. Comprehensive maintenance information to provide

SKETCH "A"

SKETCH "B"

maximum performance. This information should be read

2. Depress one end of the movable contact and push the

carefully.

contact out (see sketch "A").

DESCRIPTION

3. Remove the springs item 10.

These are three pole, three phase, non-reversing A-c

4. Remove the retainers item 9.

magnetic starters for across the line applications within the

ratings shown on the nameplate of the equipment.

CARE

These starters require no mechanical maintenance. Any

maintenance required can be performed with an electricians

SKETCH "C"

SKETCH "B"

screwdriver. For continued uninterrupted performance, renew

all of the power contacts and springs at the same time before

5. Install the new retainers item 9. (see sketch "C") Note -the

the contact tip material has worn away. When renewing the

retainer must be installed so the springs will seat over the

contacts check all terminal screws to insure they are tight and

extruded hole, with the retainer ends extending away from

secure. Suggestion refer to publication 14183 for helpful

the contacts.

information on inspecting and determining when to replace

6. Install the spring item 10 (see sketch "D").

contacts.

7. Install the contact (see sketch "B"). Insert contact, raise

end slightly and push in to seat.

RENEWAL OF OPERATING COIL

The operating coil is epoxy encapsulated and so

STATIONARY CONTACTS

constructed to provide long service life. Should the coil require

NOTE - It is not necessary to disconnect any wiring.

changing, the entire operation can be performed in a few

8. Remove the screws securing the stationary contacts.

minutes.

9. Slide the contact out of the groove in the molding. A hole in

1. Unfasten the two pan head cover screws "A" and remove

the contact plate is provided for convenient removal with a

the cover item 16.

screwdriver.

2. Tilt the top of the armature item 11 away from the coil.

10. Install the new contacts.

3. Slide the armature up and out.

CAUTION - The stationary contacts must be installed so they

4. Remove the spring plate item 12.

seat on top of the terminal plates. (See typical assembly top of

5. Pull the coil straight out.

6. Install the new coil with the coil terminal blades engaging

are renewable as a complete assembly. See page 15 for the

the coil terminal clips.

various electrical interlocks.

7. Install and seat the spring plate.

LUBRICATION

8. Slide the armature (narrow end to the right) into its seated

Do not lubricate any part of this equipment.

operating position.

Continued on page 55

9. Install the cover.

RENEWAL OF POWER UNIT

52