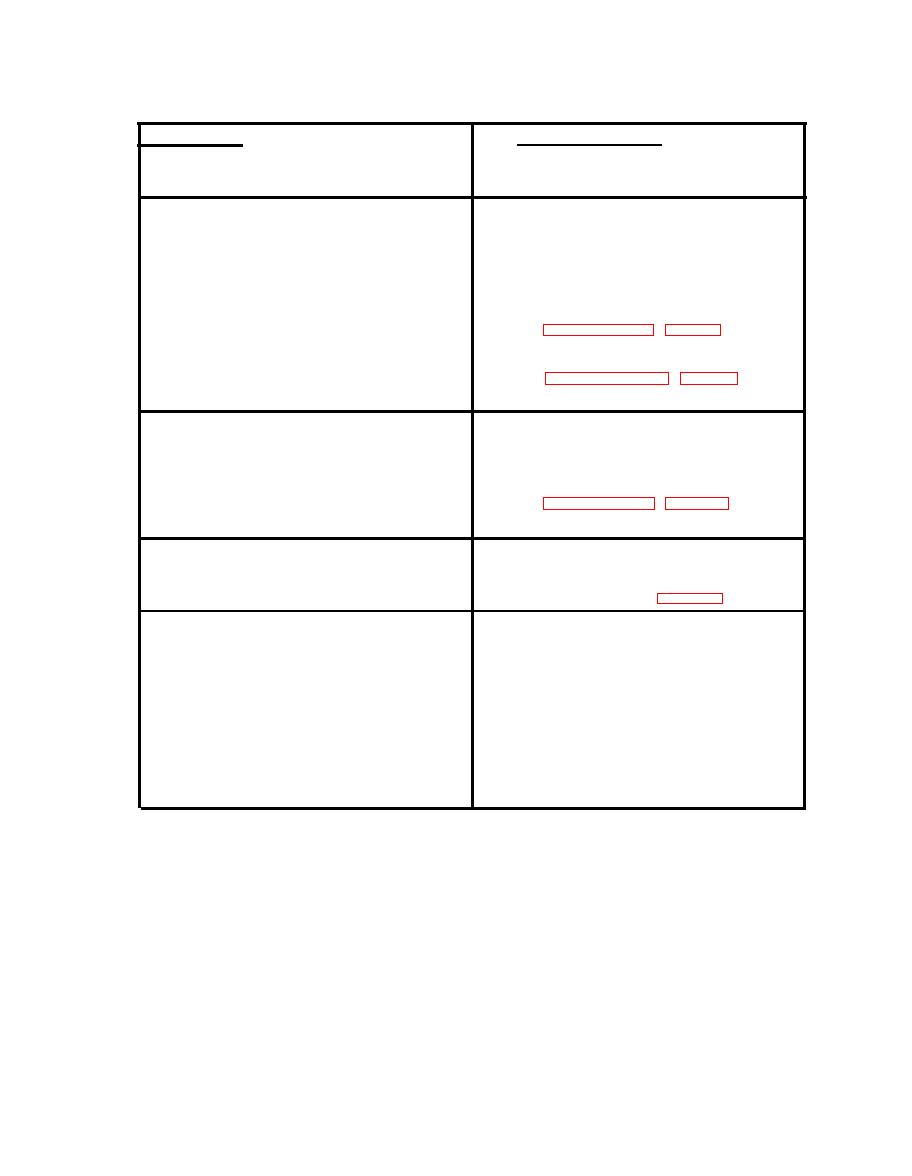

MODEL

200-AO

PREVENTATIVE

MAINTENANCE

SCHEDULE

REQUIRED

MAINTENANCE

1.

a.

Drain

Airdome

Every 4 hours of operation.

2.

a.

Check Oil Pump level in

Every 8 hours of operation.

pump crankcase.

Check "V" Belt tension,

b.

Clean Auxiliary Hose Foot

c.

Valve Strainer (if used).

d.

Check Discharge Hose Clamp

for tightness.

Blowdown Procedure.

e.

Check Valve" Packings for

f.

tightness.

Inspect Hoses for kinks,

g.

cuts or cracks.

3.

a.

Clean Fuel Filter Element

Every 40 hours of operation.

(drain water trap as needed).

b.

Oil Water Pump Piston Rod

Wicks (one squirt each).

c.

Descaling Procedure

(if required).

4.

a.

Change Water Pump break-in oil

After initial 50 hours of

(initial oil change only).

Thereafter only

operation.

when required (See Page 25).

5.

a.

Clean `Y' Strainer in Water

Every 120 hours of operation.

Supply System.

Desooting Procedure, use

b.

Use Red Devil, A.K. Part

commercially available Triple

#1002-05 (1 pint - or 1 case,

`X' Red Devil (one pint to

12 pints).

tank full of fuel).

c.

Check all plumbing, fittings,

tubing, and hoses for leaks,

cracks, etc.

Repair or

replace.