(c) The sample jar will be marked so as to

classification of defects. Defects other than those listed

identify the lot and container represented.

in these tables will be reported. Serviceability will be

withheld pending investigation by Commander,

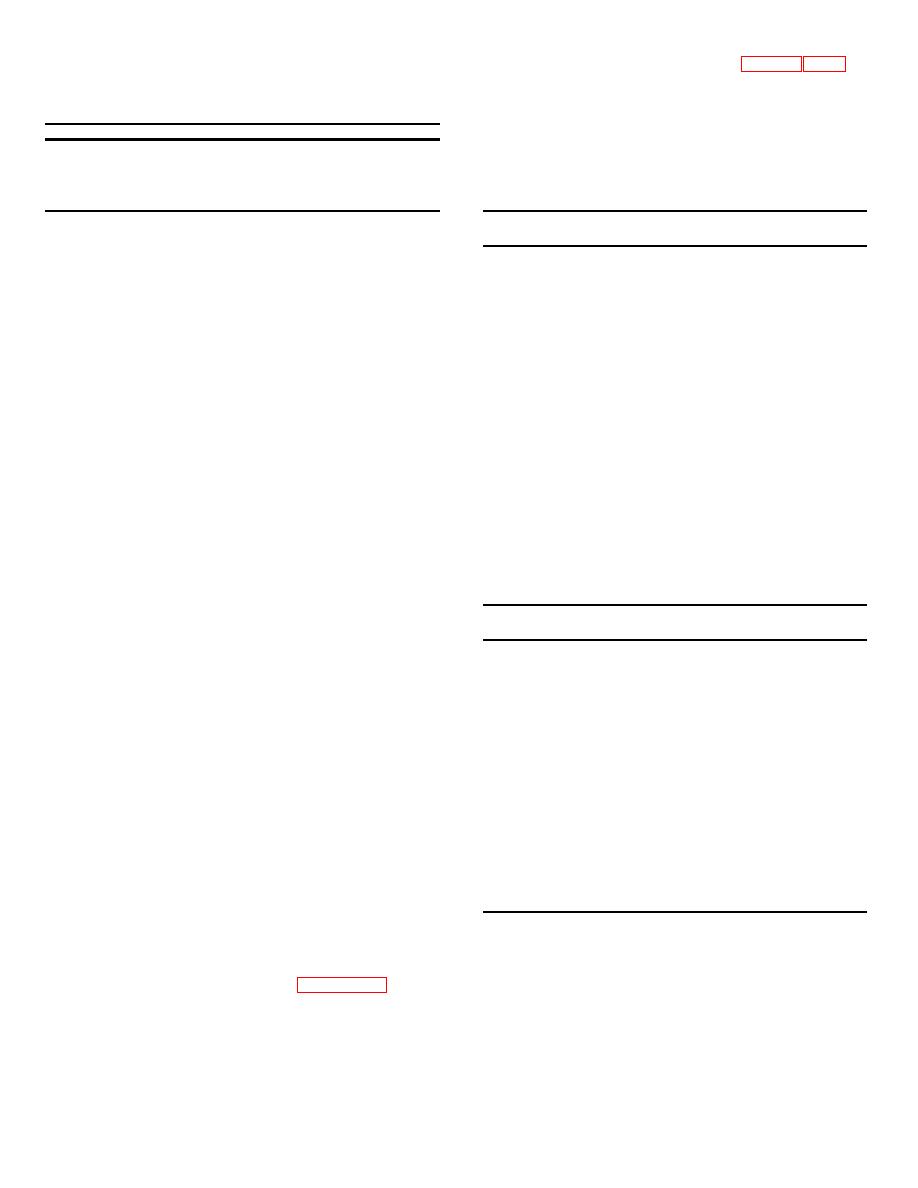

Table 1. Sampling plan.

Edgewood Arsenal, ATTN: SMUEA-PA-PQ, to

Lot size

1

2

3

4

5

6

7

8

9

0 to 100

24

0

2

24

48

1

3

8

0

determine proper defect category into which the unlisted

101 to 500

38

1

3

38

76

2

10

8

0

defect belongs.

501 to 1000

52

2

5

52

104

3

15

8

0

1001 to 5000

65

3

8

65.

130

4

19

8

0

Table 2. Impregnating Set, Clothing, Field, M3.

5001 and over

78

4

10

78

156

5

23

8

0

Inspection

Explanation of columns and symbols:

Categories

Defects

method

1 First sample size-visual.

Critical: None defined.

2 Acceptance number-major defectives (first sample).

3 Acceptance number-minor defects (first sample).

Major:

4 Second sample size-visual.

101

Component missing. (See Note 1)

Visual

5 Combined sample size-visual.

102

Chlorinated paraffin, dark honey or

Visual

6 Acceptance number-major defectives (combined samples).

charcoal colored.

7 Acceptance number-minor defects (combined samples).

Minor: None defined.

8 Sample size-test

9 Acceptance number-test.

NOTE 1.

(3) Second sample size. When the number of

Impregnating Set, Clothing, Field, M3

major defectives exceeds the quantity spec: in column

consists

of

the

following

2, but does not exceed the quantity specified in column

components: one container of

6, 'a second sample en in size to that specified in

XXCC3; one container of chlorinated

column 4, will be taken and the acceptance number

paraffin; one container of dye, olive

specified in column will be used for acceptance. A

drab, impregnating; one container of

second sample never taken for minor defectives alone.

Santromerse

"80";

one

bag

When number of minor defectives exceeds that of

containing instruction card; one

column 3, but does not exceed that of column 7 lot will

wooden packing box.

be considered serviceable. However, should a second

sample be required due to major defectives, the minor

Table 3. Packaging, Packing, Marking and Preservation

defectives will be counted reported in accordance with

Inspection

Section 7. Column will be the acceptance number for

Categories

Defects

methods

minor defectives.

Critical: None defined.

(4) Combined sample size.

When the

Major:

surveillance interval has been exceeded by 25-percent

101

Wooden boxes damaged or deterio

Visual

or when the approximate date of the last inspection is

rated to the extent that inner con-

unknown, the combined sample plan specified in

tainers are not protected or

columns 5, 6 and 7 will be used. The combined sample

handling is affected.

plan may also be used when additional assurance of

102

Inner containers damaged or deterio

Visual

quality is desired, e.g., a rework of an item where

rated to the extent that seal is

affected.

component quality unknown.

103

Inner container leaking

Visual

(5) Visual examination.

Only a visual

104

Precautionary marking missing or

Visual

examination of packing for a new or reprocessed upon

illegible on wooden box or inner

receipt at a depot storage area is required If used units

containers.

are received unprocessed at a storage area, a complete

Minor:

visual and functional examination shall be performed in

201

Straps broken or missing

Visual

accordance with instructions contained in this bulletin

202

Marking incorrect, missing

Visual

when processing and repacking.

or illegible

(6) Testing.

Overseas commands and

installations other than depots need not perform test(s)

6. Tests. a. Impregnite, XXCC3 Test.

specified in section 6. Depots that do possess testing

and/or laboratory facilities will report material in

(1) Requirements. The active chlorine content of the

accordance with the requirements of paragraph 7b.

Impregnite XXCC3 shall not be less than 10.0 percent.

(2) Equipment required. Standard chemical laboratory

5. Inspection. a. Visual Examination. The sample will

equipment as specified in "Procedure".

be examined for defects listed in 5b.

3