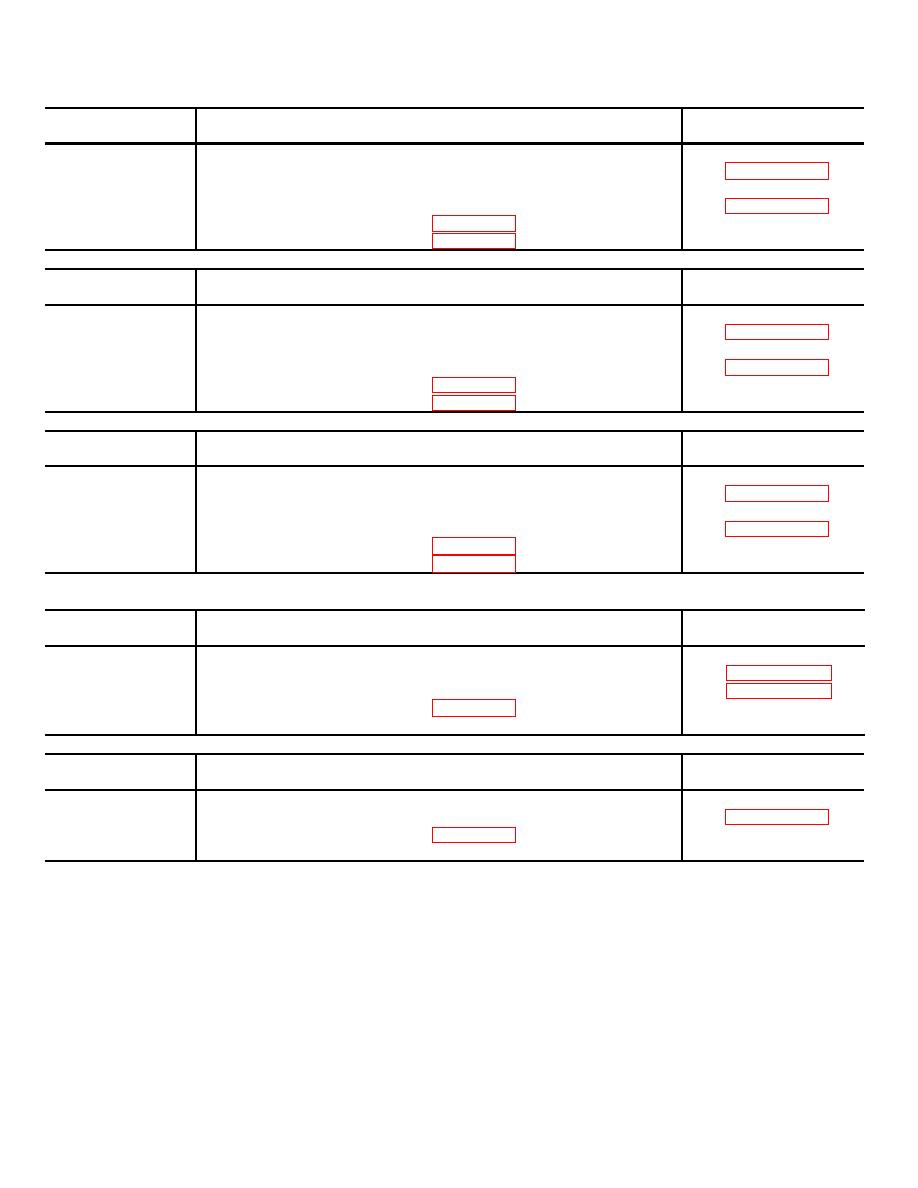

SB 740-94-8

Table E-4. Test Gage Assembly, Pressure Cylinder NSN 1040-00-605-6297

Category defect

Defect

Inspection method

No.

Critical'

1

Leakage test failure.

Test, paragraph E-4c(4)

Major:

101

Pressure gage out of calibration.

Test, paragraph E-4c(4)

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

Table E-5. Test Gage Assembly, Fuel Tank, M9 NSN 1040-00-898-1284

Category defect

Defect

Inspection method

No.

Critical.

1

Leakage test failure.

Test, paragraph E-4c(2)

Major:

101

Pressure gage out of calibration.

Test, paragraph E-4c(2)

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

Table E-6. Test Gage Assembly, Agent, Tank, M3 NSN 1040-00-898-1285

Category defect

Defect

Inspection method

No.

Critical:

1

Leakage test failure.

Test, paragraph E-4c(3)

Major.

101

Pressure gage out of calibration.

Test, paragraph E-4c(3)

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

Table E-7. Hose Assembly, Rubber, NSN 4720-00-289-2630, and NSN 4720-00-384-0494; Charging, NSN 1040-00-

859-2207; and Pneumatic, NSN 1040-00-862-2540

Category defect

Defect

Inspection method

No.

Critical'

1

Air pressure or hydrostatic pressure leakage.

Test, paragraph E-4c(1)

2

Binding of spindle.

Test, paragraph E-4c(1)

Major:

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

None defined.

Table E-8. Hose Assembly, Rubber NSN 4720-00-289-6044

Category defect

Defect

Inspection method

No.

Critical'

1

Leakage.

Test, paragraph E-4c(5)

Major:

Refer to "Quality Defect Codes" in appendix A.

Visual

specimens, or other pieces of

c. Tests.

equipment

capable

of

being

WARNING

propelled in the event of rupture.

Only authorized personnel (those

Examine test samples and test

thoroughly trained in the operation

equipment for foreign matter prior to

of the flamethrower) are permitted to

testing. Isolate the test equipment

charge, service, or function the items

and conducting hydrostatic tests.

in the service kit. Personnel shall

Where possible, locate pressure

wear

approved

eye

protective

gages and operating controls a safe

equipment when conducting tests

distance from the test site. When

involving the use of air pressure,

con-

hydrostatic pressure, etc.

Firmly

anchor all high pressure hoses, test

E-3