SB 740-94-8

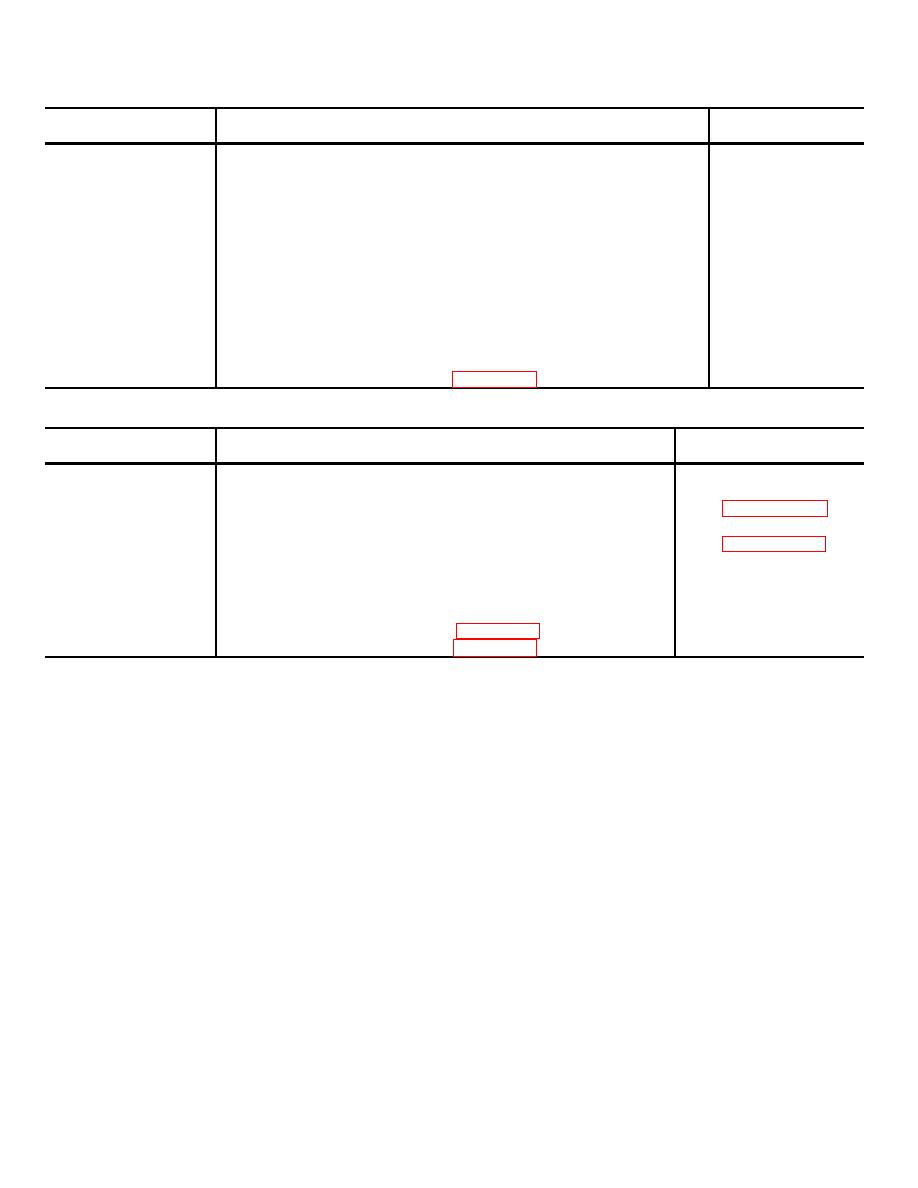

Table D-1. Packaging, Packing, Marking, and Preservation, Service Kit, M254 NS 1040-00-157-6974

Category defect No.

Defect

Inspection method

Critical

None defined.

Major:

101

Shipping or inner containers damaged, deteriorated, or weathered to

Visual

the

extent that contents cannot be adequately protected and containers

require replacement.

102

Inner container wet or mildewed.

Visual

103

Loose pack (packing so loose that contents have been damaged or are in

danger of being damaged).

Other

Refer to "Quality Defect Codes" in appendix as

Visual

Minor

201

Slight damage to shipping or inner containers but not affecting protec-

Visual

tion of contents.

Other

Refer to "Quality Defect Codes"in appendix A.

Visual

b. Classification of Defects for End Items.

Table D-2. Service Kit, Portable Riot Control Agent Disperser, M254 NSN 1040-00-157-6974

Category defect No.

Defect

Inspection method

Critical

1

Pressure check gage assembly leakage.

Test, Paragraph D-4c(1)

2

Charging hose assembly leakage.

Test, paragraph D-4c(1)

Major:

101

Inline pressure check gage assembly.

Test, paragraph D-4c(2)

102

Charging hose damaged, kinked, or cut.

Visual

103

Charging hose assembly fittings damaged.

Visual

104

Agent transfer tube damaged.

Visual

105

Protective caps missing.

Visual

Other

Refer to "'Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

c. Tests.

assembly FDWG C116-3-90). Test these components

WARNING:

as an assembly.

Only authorized personnel (those

(a) Requirement. The assembly shall

thoroughly trained in the operation

not leak when subjected to an internal air pressure of

of the service kit)- are permitted to

2100 + 50 pounds per square inch gage (psig) for a

charge, service or function the

period of 60 seconds when tested as specified.

service kit. Personnel shall wear

(b) Equipment required.

approved eye protective equipment

1. Regulated air pressure source

when conducting tests.

Firmly

(2400 + 50 psig).

anchor all pressure hoses, test

2. Water tank and water.

specimens, or other pieces of

(c) Procedure.

equipment

capable

of

being

1. Subject the assembly to an

propelled in the event of rupture.

internal air pressure of 2100 + 50 psig for a minimum

Examine test samples and test

period of 60 seconds with the assembly submerged in

equipment for foreign matter prior to

water up to the bottom of the gage.

testing. Isolate the test equipment

2. Do not allow water to contact

and specimens when conducting

the gage.

pressure tests.

Where possible,

3. Do not exceed a pressurizing

locate pressure gages and operating

rate of 500 psig per minute.

controls a safe distance from the test

4. Observe for leakage.

site.

When conducting a visual

5. Dry and disassemble the check

examination for leakage, a portable

gage with the charging hose assembly and return

shield mounted on casters may be

serviceable components to storage.

used.

The shield should be of

(2) Inline pressure check gage assembly

sufficient strength to withstand an

(DWG C116-3-63).

impact resulting from a rupture of

(a) Requirements. The Inline Pressure

the test equipment or specimen.

Check

(1) M254 service kit pressure check, gage

assembly (DWG Dl116-3-62) and charging hose

D-2