01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

copper wire. This problem is compounded because

the wire insulation prohibits detection of breaks in the

silver plating until damage is extensive. This "red

plague" is readily identifiable by the presence of a

brown-red powder deposit on the exposed copper.

Silver plating over nickel plate does not exhibit the red

plague phenomenon.

3-10.12. GOLD. Traditionally considered the best

coating for corrosion resistance and solderability, gold

is used on printed circuits, semiconductors, leads, and

contacts. Gold is usually applied in a thin layer over

nickel, silver, or copper. Gold is a noble metal (pure

metal in nature) and does not normally corrode; however,

a slight deposit will appear as a darkening of reflecting

surfaces. Tarnish removal is critical on gold components

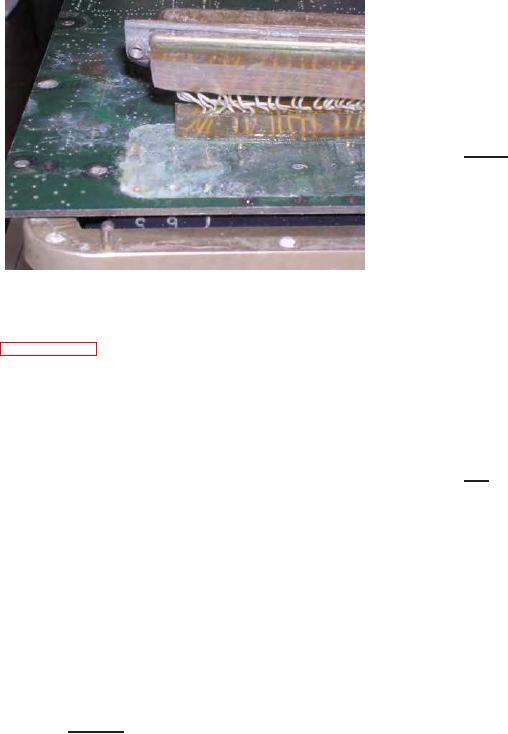

Figure 3-29. Corroded Circuit Card

because of the very thin coatings used. Gold plated over

silver or copper in thin layers accelerates corrosion over

the less noble metals (silver or copper). This occurs at

corrosion products on the corroded part (see

pores or pinholes in the gold. This corrosion is readily

Figure 3-29). Sometimes copper or copper alloy

identified as darkening of the silver or blue-green deposits

surfaces tarnish to a dull gray-green color (patina) and

on the copper. "Purple plague" is a brittle gold-aluminum

the surface will remain relatively smooth. This

compound formed when bonding gold to aluminum.

discoloration is the result of the formation of a fine-

The growth of such a compound can cause failure in

grained, airtight copper oxide crust. This crust offers

microelectronic interconnection bonds.

good protection for the underlying metal in ordinary

situations. However, exposure of copper and copper

3-10.13. TIN. The use of tin in solder is a well-known

alloys to moisture or salt spray causes the formation of

application. However, tin plating is also common on

blue-green salts, indicating active surface corrosion,

avionic RF shields, filters, crystal covers, and automatic

which should be removed. When coupled with most

switching devices. Tin has the best combination of

metals used in aircraft construction, copper is the less

solderability and corrosion resistance of any metallic

active metal and greatly accelerates corrosion of iron,

coating. However, tin has a tendency to grow "whiskers"

steel, aluminum, and magnesium. Examples are usually

on tin plated wire and other plated applications.

found in electrical components and in areas where

copper bonding strips or wires are fastened to an

3-11. DEGRADATION OF NON-METALS. Non-

aluminum chassis or structural components. Protective

metallic materials (plastics, elastomers, paints and

paint coatings are seldom required because of the

adhesives) are not subject to electrochemical corrosion,

inherent resistance of the metal. However, paint finishes

since ions are not easily formed from non-metallic

may be applied for decorative purposes or if the normal

materials and since the electrical conductivity of non-

tarnish or green patina on the copper is objectionable.

metals is extremely low. The degradation of non-metals

depends on the chemical makeup of the material and

3-10.11. SILVER. Silver is used as a plating material

the nature of the environment. In general, aircraft non-

over copper in waveguides, miniature and

metallic materials are selected for their performance

microminiature circuits, wires, contacts, high frequency

properties (flexibility, transparency, strength, electrical

cavities, tank circuits, and RF shielding. Silver does not

resistance). Also, resistance to heat, impact, abrasion,

corrode in the ordinary sense, although it will tarnish in

ultraviolet radiation, moisture, ozone and other

the presence of sulfur. The tarnish appears as a brown

detrimental gases, as well as operational fluids such

to black film. The tarnish is silver sulfide and may or

as hydraulic fluid, lubricants, cleaners, and deicing

may not be detrimental to circuit electrical

fluids, must be considered. However, the use of

characteristics, depending on the application. When

unauthorized maintenance chemicals and procedures

silver is plated over copper there can be an accelerated

can accelerate degradation. In almost all cases, the

corrosion of the copper. This occurs through galvanic

deterioration of a nonmetallic material permits moisture

action at pinholes or breaks in the silver plating. One

intrusion. This creates physical swelling, distortion,

example of this is the deterioration of silver plated