01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

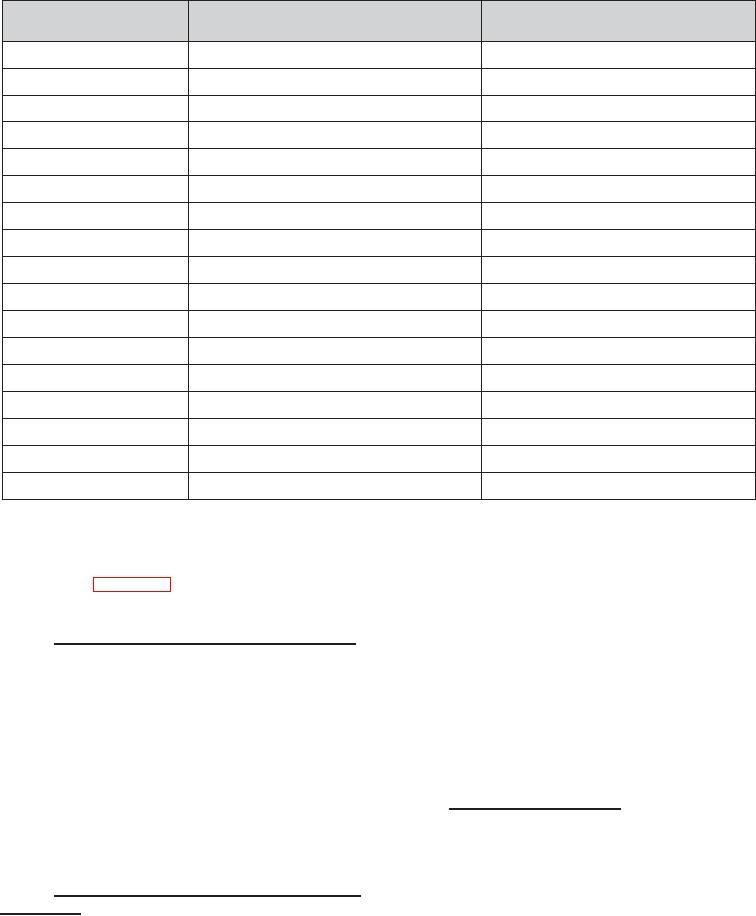

Table 3-2. Effects of Deterioration on Nonmetals

TYPE OF ATTACK TO WHICH

APPEARANCE OF

MATERIAL

MATERIAL IS SUSCEPTIBLE

DETERIORATION

Acrylic

UV light, moisture, solvents

Discoloration, cracking

Adhesive

Dirt, UV light, solvent, moisture

Cracking, peeling

Ceramic

Extreme heat

Discoloration, cracking

Cloth

Dry rot, mildew

Discoloration, tears, dust

Moisture, scratchess

Peeling, flaking, bubbling

Cork

Moisture, mildew, dry rot

Discoloration, dust, peeling

Elastomer

Heat, UV light, excessive cycling

Cracks, crazing, discoloration

Encapsulation

UV light, moisture

Cracking, peeling, disbonding

Felt

Moisture, mildew

Discoloration, looseness

Glass

Heat, mechanical damage (broken)

Cracked, discolored

Laminates

UV light, moisture, solvents

Discolored, disbond, delamination

Paint

Moisture, heat, humidity

Bubbles, peeling, cracking

Plastic

UV light, heat, abrasion

Discoloration, cracks, deformation

Polymers

Extreme heat, solvents

Discoloration, deformation

Potting Compounds

UV light, moisture, heat

Discoloration, cracks, deformation

RTV (noncorrosive)

Moisture, UV light, heat

Peeling, debonding, discoloration

Sealants

Moisture, UV light, heat

Peeling, debonding, discoloration

mechanical failure through cracking, and altering of

assembly. These materials are considered nearly as

electrical characteristics. The most common nonmetals

effective as hermetic sealing. Typical materials used for

used in aircraft systems and their modes of deterioration

this purpose are epoxy, polyurethane, silicone rubber,

are listed in Table 3-2. Examples of nonmetallic

acrylic, and varnish. Because these materials are

deterioration are discussed in the following paragraphs.

organic, they are susceptible to moisture, varying

temperature, and fungus. Moisture accumulates when

3-11.1. GRAPHITE/CARBON FIBER COMPOSITES.

incorrect repair procedures cause imperfections and

Graphite or carbon fiber composites are materials which

bubbles, or when the coating is applied too thick. High

consist of reinforcing fibers in a matrix made of organic

temperatures may cause corrosive vapor to outgas

resin, usually epoxy. They are an important class of

from encapsulants and conformal coatings. This

aviation materials because of their high strength-to-

problem is of special concern if a circuit component

weight ratios and high stiffness. Composite materials

burns on a conformal coated circuit board. These

are found in aircraft structure, connectors, enclosures,

gaseous vapors can penetrate under circuit board

EMI seals and gaskets. Since carbon is the least active

coatings and cause major corrosion damage.

metal in the galvanic series, it will accelerate the

corrosion of any aircraft metal to which it is coupled.

3-11.3. POTTING COMPOUNDS. Potting compounds

Insulation between graphite or carbon epoxy

are used to encase a part or component, such as in an

composites and other metals is necessary to prevent

electrical connector. Generally, potting compounds

dissimilar metal attack on the attached part.

are considered to be a good seal against moisture

when correctly applied. Problems occur when potting

3-11.2. E N C A P S U L A N T S A N D C O N F O R M A L

compounds are cured too quickly, not mixed properly,

COATINGS. Encapsulants and conformal coatings are

or the surface is not cleaned completely. Aging of

used to envelop an avionic component, module or

certain potting compounds can cause the potting

compound to harden and become brittle, or soften and