01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

Table 3-1. Effects of Corrosion on Metals

TYPE OF ATTACK TO WHICH

APPEARANCE OF

ALLOY IS SUSCEPTIBLE

CORROSION PRODUCT

Surface pitting, intergranular, exfoliation, stress

Aluminum Alloy

White to gray powder

corrosion and fatigue cracking, and fretting

White, powdery, snowlike mounds,

Magnesium Alloy

Highly susceptible to pitting

and white spots on surface

Carbon & Low

Surface oxidation and pitting;

Reddish-brown oxide (rust)

Alloy Steel

surface and intergranular corrosion

(4000-8000 series)

Crevice corrosion; some pitting in marine

Stainless Steels

Rough surface; sometimes a red, brown,

environments; corrosion cracking; intergranular

or black stain

corrosion (300 series); surface corrosion (400

(300-400 series)

series)

Highly corrosion resistant; extended or repeated

No visible corrosion products at low temperature.

contact with chlorinated solvents may result in

Colored surface oxides develop above

Titanium Alloy

degradation of the metal's structural properties.

700 F (370 C)

Cadmium plated tools can cause embrittlement.

Cadmium (used as

From white powdery deposit to brown or black

a protective plating

Uniform surface corrosion

mottling of the surface.

for steel)

Pitting (promotes rusting of steel where pits

No visible corrosion products; blistering of plating

Chromium (plate)

occur in plate)

due to rusting and lifting

Nickel-base Alloy

Generally has good corrosion resistant qualities;

Green powdery deposit

(Inconel, Monel)

susceptible to pitting in sea water

Nickel does not corrode, but promotes corrosion

Electroless Nickel

Pitting and flaking of surface plating

of aluminum base metal where pits occur in the

(used as a plating)

plating

Copper-base Alloy,

Surface and intergranular corrosion

Blue or blue-green powdery deposit

Brass, Bronze

Silver

Will tarnish in presence of sulfur

Brown to black film

Gold

Highly corrosion resistant

Deposits cause darkening of reflective surfaces

Tin

Subject to whisker growth

Whisker-like deposits

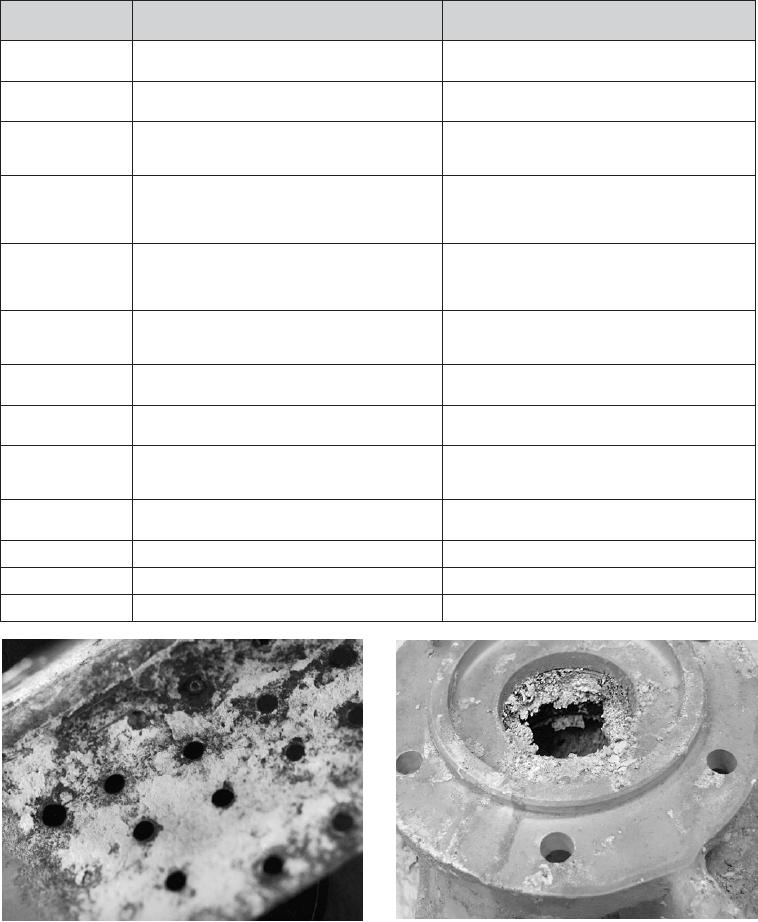

Figure 3-24. Magnesium Corrosion Products

Figure 3-23. Aluminum Surface Corrosion Products