01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

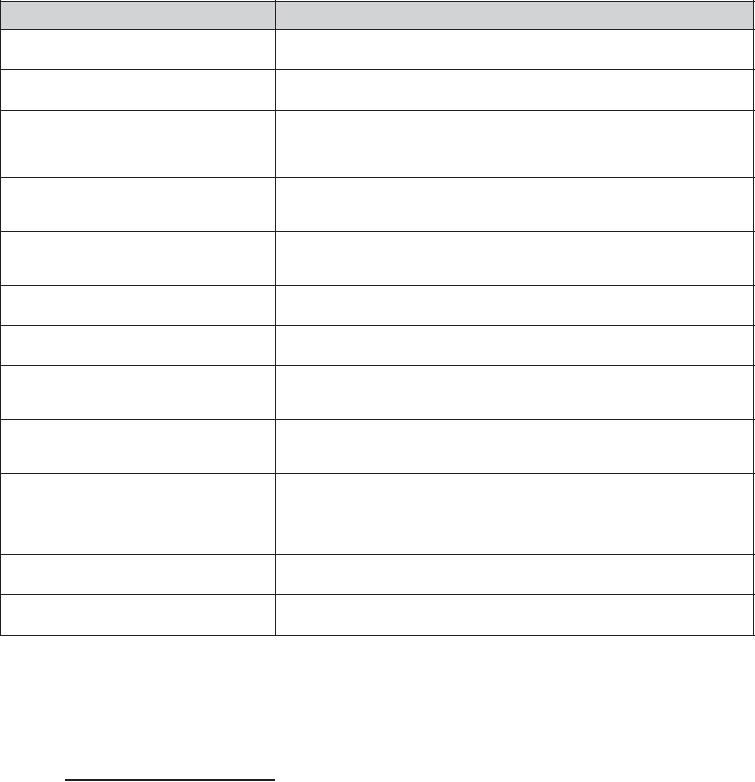

Table 3-3. Effects of Moisture and Fungi on Various Materials

PART OR MATERIAL

EFFECT

Moisture causes swelling that causes the support to misalign, resulting in

Fiber: washers, supports

binding of supported parts. Destroyed by fungi.

Moisture forms electrical leakage paths, causing flashovers and crosstalk.

Fiber: terminal strips, insulators

Insulating properties are lost. Destroyed by fungi.

Moisture causes insulating properties to be lost. Leakage paths cause

Laminated plastics: terminal strips, boards,

flashovers and crosstalk. Delamination occurs and fungi grow on surface and

switchboard panels, tube sockets and coil

around edges. Expansion and contraction under extreme temperature

forms, and connectors

changes.

Molded plastics: terminal boards,

Machined, sawed, or ground edges of surfaces are supporters of fungi,

switchboards panels, connector, tube

causing shorts and flashovers. Fungal growth reduces resistance between

sockets and coil forms

parts mounted on plastic to such an extent that the parts are useless.

Cotton linen, paper, and cellulose

Moisture causes loss or impairement of insulating and dielectric properties,

derivatives: insulation, coverings, webbing,

causing arcing, flashovers, and crosstalk. Destroyed by fungi.

belting, laminations, dielectrics

Wood: cases, houses and housings, plastic

Dry rot, swelling, and delamination are caused by moisture and fungi.

fillers, masts

Moisture and fungi destroy tanning and protective materials, causing

Leather: straps, cases, gaskets

Fungi grow on organic dust, insect track, insect feces and dead insects.

Glass: lenses, windows

Dead mites and fungal growth on glass obscure visibility and corrode nearby

metal parts.

Fungi-inhibiting waxes that are not clean support the growth of fungi, cause

Wax: for impregnation

destruction of insulating and protective qualities, and permit entrance of

moisture that destroys parts and unbalances electrical circuits.

High temperature and moisture vapor cause rapid corrosion. Fungus and

bacterial growth produce acid and other products that speed corrosion,

Metals

etching of surfaces, and oxidation.This interferes with the operation of moving

parts, screws, and causes dust between terminals, capacitors, plates or air

condensers, which in turn may cause noise, loss in sensitivity, and arc-overs.

Metals may have different corrosion potentials. When moisture is present,

Metal, dissimilar

one of the metals (anode) corrodes.

Residual soldering flux on terminal boards holds moisture, which speeds up

Soldered joints

corrosion and growth of fungi.

or by drying the interiors of compartments with

present. The metabolism of these bacteria requires

desiccants. However, some moisture-proof coatings

them to obtain food sources by oxidizing inorganic

are attacked by microorganisms, especially if the

compounds such as iron, sulfur, hydrogen, and carbon

surface on which they are used is already contaminated.

monoxide. The resultant chemical reactions cause

Some microorganisms can survive in spore form for

corrosion.

long periods while dry, and can become active when

moisture is available. When desiccants become

3-14.2.2. Microbial Growth Requirements. Fungi make

saturated and unable to absorb moisture in the affected

up one class of microorganism that feeds on organic

area, microorganisms can begin to grow. Dirt, dust,

matter. Low humidity levels will inhibit the growth of

and other airborne contaminants are the least

most species of fungi and bacteria. Ideal growth

recognized contributors to microbial attack. Unnoticed,

conditions for most fungi and bacteria are temperatures

small amounts of airborne debris may be sufficient to

between 68 and 104F (20 and 40C) and relative

promote fungal growth.

humidities between 85 and 100%. It was formerly

believed that microbial attack could be prevented by

applying moisture-proof coatings to nutrient materials