NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

d. Stray electrical currents can cause corrosion.

e. Active metals and dissimilar metals in contact

are often unprotected.

f. Closed boxes can produce condensation via

normal temperature changes during flight.

g. Avionic systems have many areas that trap

moisture.

h. Hidden corrosion is difficult to detect in many

avionic systems.

i. Many materials used in avionic systems are

subject to attack by bacteria and fungi.

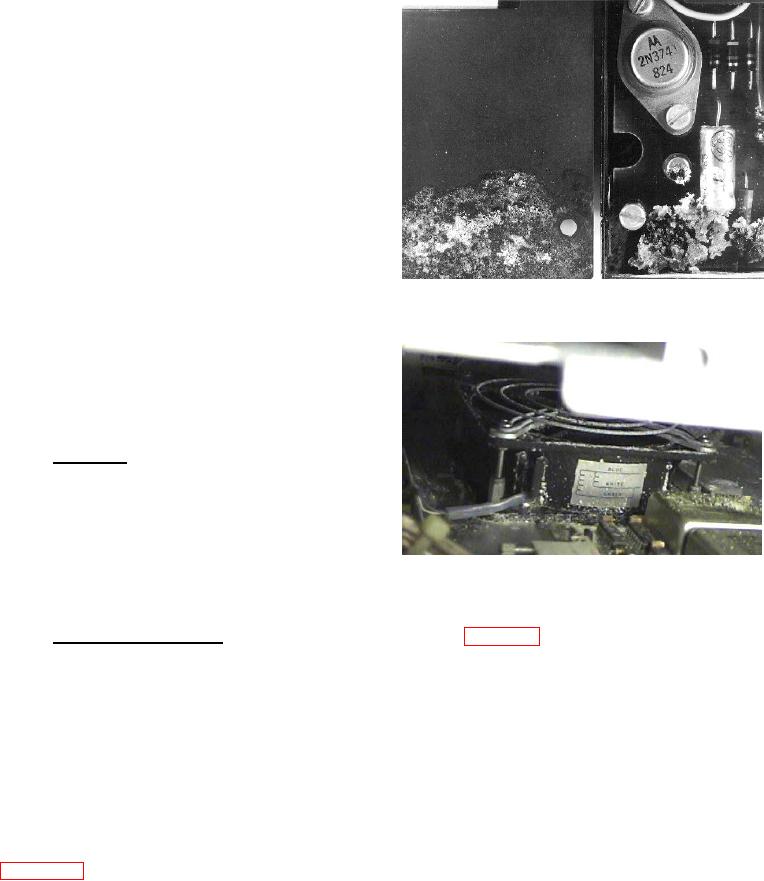

Figure 3-1. Corrosion Caused by Blown Capacitor Acid

j. Organic materials are often used that, when

overheated or improperly or incompletely cured, can

produce vapors. These vapors are corrosive to

electronic components and damaging to coatings and

3-2. INSPECTION PROCESS.

3-2.1. GENERAL. Frequent corrosion inspections are

essential to the overall corrosion control program. By

early detection, identification, and treatment, the costs

resulting from corrosion are minimized. Without regular

systematic inspections, corrosion will seriously damage

avionic equipment. The following paragraphs describe

some of the basic aspects of visual inspection for

Figure 3-2. Frequency Test Set Corroded

corrosion and the telltale signs associated with various

While in Storage

types of corrosion damage.

3-2.2. INSPECTION FACTORS. Calendar-based and

shown in Figure 3-2. This corrosion occurred while in

phase maintenance inspections shall be in accordance

storage.

with parent service or command directives. However,

extreme humidity, temperature, atmospheric conditions

d. Length of time aircraft is nonoperational.

and time shall be considered when determining the

frequency of corrosion inspections. The following

e. Nonpressurized equipment and equipment bays.

factors shall be considered when establishing local

inspection intervals:

f. Antenna and externally mounted avionic

packages such as electronic countermeasure (ECM)

a. Operational environment.

pods.

b. Known corrosion-prone areas such as battery

g. Equipment mounted in water entrapment areas.

components, ram air turbines, and electrical bonds.

Figure 3-1 shows corrosion caused by a blown

h. Equipment susceptible to particularly harsh

capacitor.

environments, such as sonobuoys and magnetic

anomaly detection (MAD) systems.

c. Length of storage time, with respect to equipment

and components. A corroded frequency test set is