NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

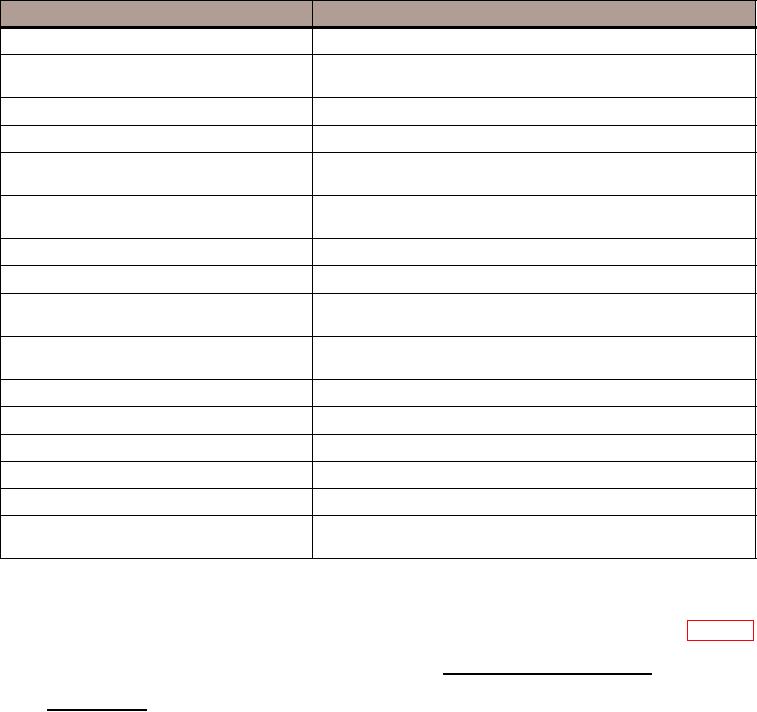

Table 3-1. Effects of Corrosion on Avionic Equipment

Component

Antenna Systems

Shorts or changes in circuit constants and structural deterioration

Batteries

High resistance at terminals, failure of electrical contact points, and

structural deterioration of mounting. Erroneous cockpit signals

Bus Bars

Structural and electrical failures

Chassis, Housings, Covers, and Mount Fames

Contamination, pitting, loss of finish, and structural deterioration

Coaxial Lines

Impedance fluctuations, loss of signals, and structural deterioration of

connectors

Control Box Mechanical and Electrical Tuning

Intermittent operation and faulty frequency selection

Linkage and Motor Contacts

Display lamps and Wing Lights

Intermittent operation, mechanical and electrical failures

Fluid Cooling System Lines

Failure of gaskets, pitting, and power loss

Multi-pin Cable Connectors

Shorts, increased resistance, intermittent operation, and water seal

deterioration

Plugs, Connectors, Jacks and Receptacles

Shorts, increased resistance, intermittent operation, and reduced

system reliability

Disintegration of insulation, and wire/connector deterioration

Printed Circuits and Microminiature Circuits

Shorts, increased resistance, component and system failures

Relay and Switching Systems

Mechanical failure, shorts, intermittent operation, and signal loss

Shock Mounts and Supports

Deterioration and loss of shock effectiveness

Water Traps

Structural deterioration

Waveguides

Loss of integrity against moisture, pitting, reduction of efficiency and

structural deterioration

(oxides) and organic contaminant films. Insulating

corrosion in electronic systems. The typical effects of

films form during nonuse and prevent startup of

corrosion on avionic equipment are listed in Table 3-1.

equipment. Once the equipment is activated, the

insulating film is removed by friction between surfaces.

3-1.6. SPECIAL CONSIDERATIONS. The control of

corrosion in avionic systems is not unlike that in

3-1.5. ELECTRONIC. Moisture and contamination

airframes. Procedures used for airframes are applicable

penetrate into electronic systems causing many

to avionics with appropriate modifications. The general

detrimental effects, corrosion being one of these. In

differences in construction and procedures between

most electronic systems, circuit areas have been

airframe and avionics relative to corrosion control are

minimized for faster signal processing and higher

as follows:

density. This means that most circuit paths are thin, or

small in cross-sectional area, and that individual circuit

a. Avionics rely on less durable protection systems.

paths are close together. In such systems, trace

amounts of moisture and contamination may cause

b. Very small amounts of corrosion can make

system failure. For example, if the aluminum surface of

avionic equipment inoperative, as compared to

an integrated circuit (IC) is contaminated, affected

airframes.

circuit paths may become blocked. This extreme

sensitivity requires special caution when dealing with

c. Dissimilar metals are often in electrical contact.