NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

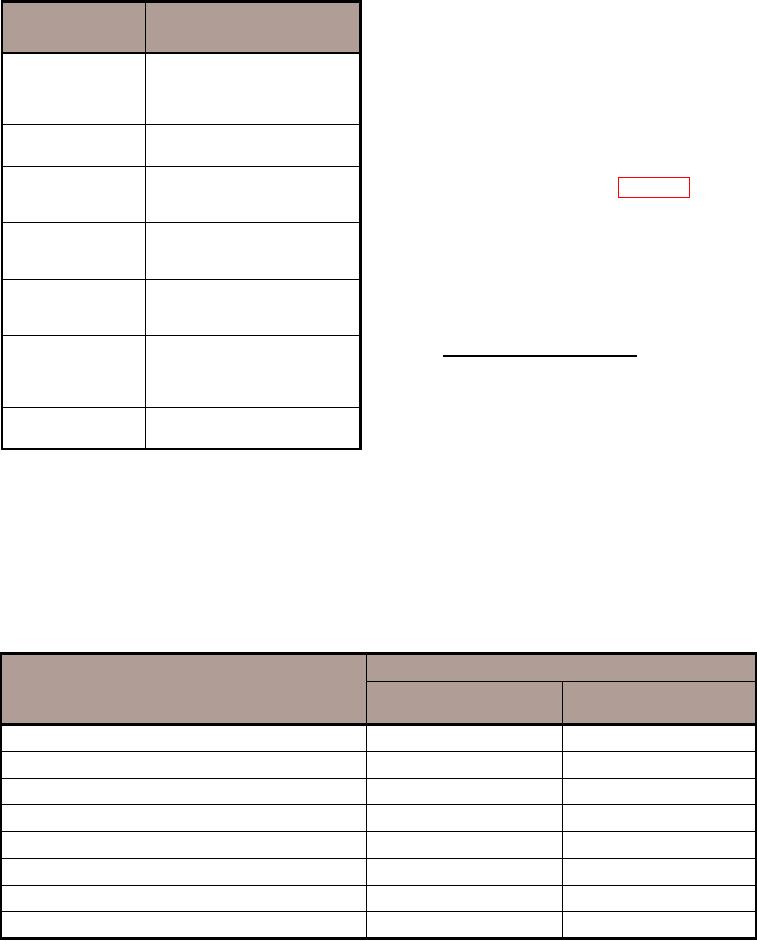

Table 8-1. Typical Prime Charge Sources

maintenance work place. For example, latex finger

cots rubbed against a plastic box can charge to 6 kV

while bare fingers can generate only 200 volts. Note

Prime Source

Composition/Application

that even 200 volts of static charge can degrade or

destroy some ESDS devices. An additional source of

Work Surfaces

Formica

static charge is created during wave soldering and

Finished wood

Synthetic mats

general cleaning operations. Normally, low surface

Metal plates

energy solvents such as chlorinated hydrocarbons are

used in these operations. Although such solvents

Floors

Wax-finished

provide excellent cleaning capacity, rapid evaporation,

Vinyl

and noncorrosive properties, they increase static

Clothes

Clean room smocks

control problems. As indicated in Table 8-3, rubbing a

Personal garments (i.e., wool,

printed circuit board (PCB) with a solvent saturated

nylon, dacron)

cloth can generate substantial charges. This is much

Chairs

Finished wood

like rubbing the PCB with a Teflon or chlorinated

Vinyl

plastic film. This problem can be solved by using a

chlorinated-glycol hydrocarbon antistatic solvent.

Packaging/Handling

Polyethylene bags, wraps,

envelopes; bubble pack; foam;

8-4. TYPES OF ESD FAILURES.

plastic trays, boxes

Repair/Cleaning Areas

Spray cleaners

8-4.1. INTERMITTENT FAILURES. ESD can cause

Solder suckers

intermittent or upset failures as well as hard failures of

Solder irons

aircraft electronics. Intermittent or upset failures can

Solvent brushes

occur on Large Scale Integration (LSI) ICs when

Moving Air

Forced air drying of

equipment is in operation. This is usually characterized

equipment/components

by a loss of information or temporary distortion of its

functions. No apparent hardware damage occurs and

proper operation resumes automatically after ESD

environment eliminate contamination during handling

exposure and system reset. Upset failures can be the

of devices. However, their use in conjunction with

result of a spark near the equipment. The EMP

other materials often result in a very high static charge.

generated by the spark causes erroneous signals to

Specifically, synthetic materials are used frequently

be routed through equipment circuitry. Upset failures

because they are nonporous, flexible, and easily

can also occur by capacitive/inductive coupling of ESD

fabricated. Static charges can be generated from

pulses or direct discharge through a signal path

common materials found in the clean room or

providing an erroneous signal.

Table 8-2. Typical Electrostatic Charges

Electrostatic Charge (Volts)

Means of Generation

10 to 20%

65 to 90%

Walking across carpet

35,000

1,500

Walking over vinyl floor

12,000

250

Worker at bench

6,000

100

Maintenance Action Form (MAF) bag (work card envelope)

7,000

600

Common poly bag picked up from bench

20,000

1,200

Work chair padded with polyurethene foam

18,000

1,500

Styrofoam coffee cup

5,000

Undetermined

Plastic solder sipper

8,000

Undetermined