NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

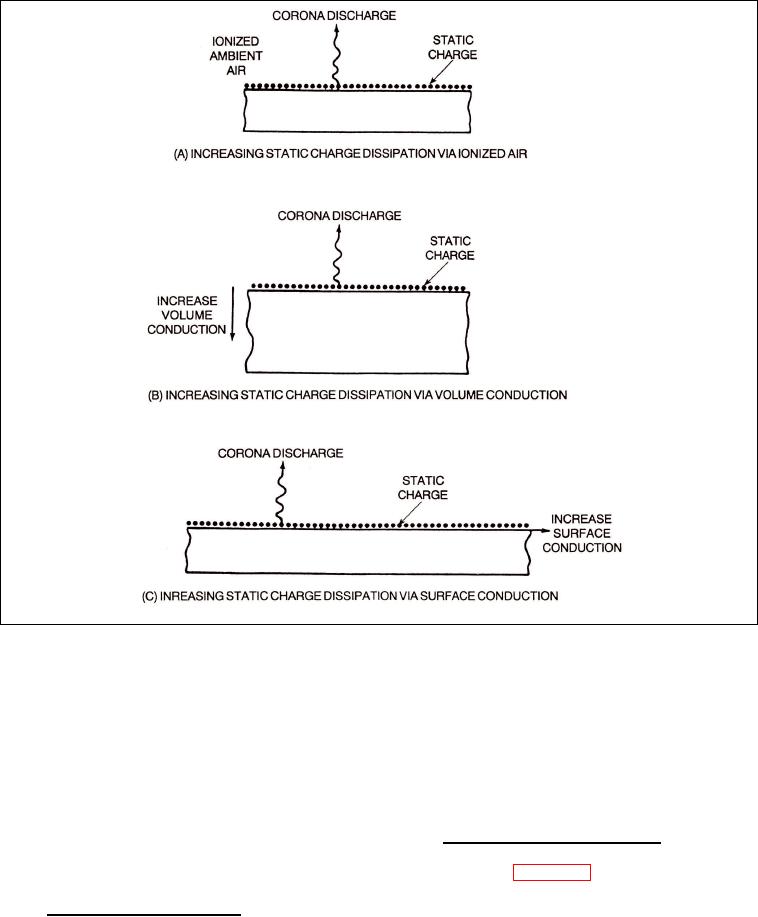

Figure 8-5. Dissipation of Static Charges

ESD devices must take precautionary steps. It would

8-9. RECOMMENDED PRACTICES FOR ESD

be futile for component repair personnel to take full

EQUIPMENT, MODULES, AND COMPONENTS.

precautions, only to turn the repaired item over to

t e c h n i c i a n s who ignore all precautions and

NOTE

inadertvently destroy the module. Maintenance

S o m e ESD control procedures involve

personnel should refer to MIL-HDBK-773, MIL-HDBK-

conditions or operations that may produce

263, and MIL-STD-1686 for more detailed descriptions

corrosion. Special handling methods and

of ESD control measures.

materials must be used to prevent equipment

damage. In case of conflict, refer to the

8-9.2. ESD PACKAGING PRACTICES. Packaging of

applicable service directives and TO 00-25-

ESD items must only be done at an ESD protective

234 (Air Force only).

workstation. See Figure 8-6.

8-9.1. BASIC ESD PRECAUTIONS. ESD precautions

a. Packaging for electrostatic discharge protection

are not limited to manufacturing or component repair

requires the use of one or more of the following

personnel only. Anyone handling, processing, or using

materials: