NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

8-7.2. GENERAL SOLUTIONS TO STATIC CHARGE

PROBLEMS. The techniques that can be used include

i n c r e a s i n g corona discharge by ionization of

s u r r o u n d i n g air, increasing surface electrical

conductivity, or increasing bulk material electrical

conductivity. It is often very difficult to promote corona

discharge into the air for most avionics systems.

Therefore, static protection has been commonly brought

about by methods that would increase the surface and/

or volume electrical conductivity.

8-7.3. ESD PROBLEM SOLUTIONS. To protect ESD

devices, it is important to provide a conductive path to

ground. This provides for rapid dissipation of static

electrical charge. Practical solutions of dealing with

ESD may be summarized as follows:

a. Dissipate by distribution over conductive surface.

b. Shield ESD sensitive components from induced

potentials (shielding).

c. Provide conductive path to ground.

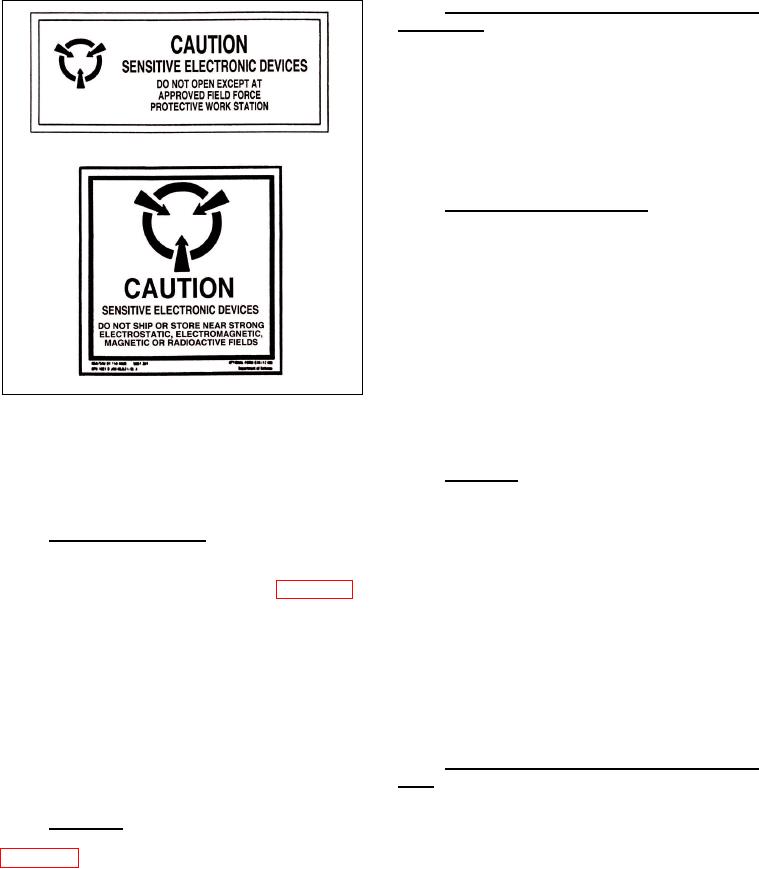

Figure 8-4. Examples of Typical Markings on ESD

Sensitive Item Package

8-8. EFFECTS OF CORROSION.

users should be alert for different markings as well as

8-8.1. GENERAL. Corrosion can degrade the electrical

those shown. The presence of the symbol indicates

and mechanical properties of ESD protection systems.

the item is considered an ESD sensitive device.

The exposure of ESD devices/ESD protection systems

to various environmental conditions can significantly

8-6.3. ESD CLASSIFICATION. Electronic components

increase their susceptibility to damage from the

subject to ESD related damage or failure are grouped

discharge of static electricity. Under field service

as ESD materials. These are grouped into three major

conditions, military avionics experience corrosion

categories as defined in MIL-STD-1686 (Table 8-4):

between metal surfaces such as electrical bonding/

grounding connections. This problem is two-fold. First,

a. Class 1: Extremely Sensitive: Voltage ranges

corrosion between metal surfaces in avionics creates

from 0-2 kV.

structural weaknesses that undermine its effectiveness

to shield ESDS components from induced potentials.

b. Class 2: Sensitive: Voltage ranges from 2-4 kV.

Second, the corrosive process creates nonconductive

products that decrease the paths of conduction of

c. Class 3: Less sensitive - Voltage ranges from

static charge away from the device or assembly.

4-16 kV (Class 3 items are sometimes considered

non-ESD sensitive).

8-8.2. CORROSION-INDUCED CHARACTERIS-

TICS. Although no valid method of evaluating the

8-7. DISSIPATION OF STATIC CHARGES.

effect of corrosion on ESD sensitivity exists presently,

certain trends can be identified. ESD protection for

8-7.1. GENERAL. Dissipation of static charge usually

enclosed avionic equipment can degrade in perfor-

occurs by one of three different paths as shown in

mance over time. This occurs often after only 3 or 4

Figure 8-5. These paths represent corona discharge

months of exposure to the field environment and

into the air, surface conduction to ground and

normal use. Galvanic corrosion is usually the principal

conduction through the volume of the material to

form of attack. This type of corrosion can rapidly

ground. Therefore, the tendency to build up static

charge may be decreased by increasing these paths of

conduction away from the material.