NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

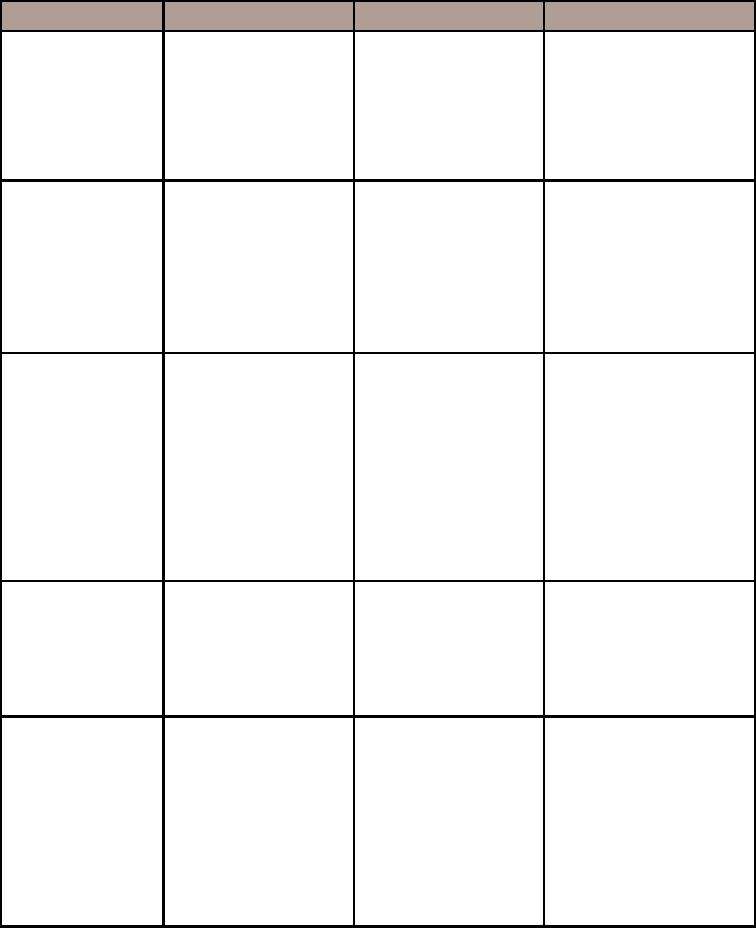

Table 9-1. Preservative Compounds for Avionic Equipment

Specification

Intended Use

Application

Restrictions

Corrosion Preventive

Displacement of water; short

Do not use on interior surfaces of

Apply a soft very thin (0.5 mil)

Compound,

term corrosion protection of

electrical connectors, coaxial

translucent, light amber

Water-Displacing,

coating by dipping, spraying,

metal surfaces during

connectors, receptacles or

Ultra-Thin Film,

shipment, storage, and in-

brushing, or spraying from a

waveguides. Do not use around

MIL-C-81309 Type II

service use; corrosion

oxygen, oxygen fittings, or

pressurized container. Can be

protection of moving parts

oxygen regulators, since fire or

removed with cleaning

where some lubrication is

solvent.

explosion may result.

required, such as hinge

areas, bomb racks, and

sliding parts. Also used as a

waterless cleaner.

Corrosion Preventive

General preservative for

Not intended for use on exterior

Apply by spraying an even,

Compound,

thin film to the surface. Can

internal areas of avionic

surfaces of avionic equipment.

Water-Displacing,

be removed with cleaning

equipment; internal areas of

Deposits a thin film which must

Ultra-Thin Film,

solvent.

electrical connectors,

be must be removed for proper

Avionics Grade,

receptacles, and solder joints.

function of contact points and

MIL-C-81309 Type III

Contains water-displacing

other electromechanical devices

properties.

where no slipping or wiping

action is involved.

Do not use around oxygen,

oxygen fittings, or oxygen

regulators, since fire or explosion

may result.

Corrosion Preventive

General preservative for

Apply by brush or spraying an

Do not use on interior surfaces or

Compound,

external surface exposed to

even thin film to the surface.

avionic equipment.

Solvent Cutback,

elements and moisture,

Material presents a semi-

Do not use on interior surfaces of

Cold Application

including: mounting racks,

transparent film. Can be

electrical connectors, coaxial

MIL-PRF-16173 Grade 4

shelving, brackets, radar

removed with cleaning

connectors, or receptacles.

plumbing, shock mounts, rigid

solvent.

Do not use around oxygen,

mounts, antenna hardware,

oxygen fittings, or oxygen

general hardware, hinges

regulators, since fire or explosion

fasteners, ground straps; and

may result.

exterior surfaces of electrical

connectors, coaxial

Must be applied over water

connectors, and receptacles.

displacing corrosion preventive

compound, MIL-C-81309

Type III, to accomplish complete

water-displacing and preservative

on all areas exposed to elements

and moisture.

Corrosion Preventative

Temporary repair of paint

Do not use on interior surfaces or

Apply by brush or spraying an

Compound, Clear

damage to exterior surfaces

avionic equipment.

even thin film to surface. A

(Amlguard)

such as cracks and

second coat may be applied

Do not use on interior surfaces of

MIL-DTL-85054

scratches; preservative for

after 30 minutes.

electrical connectors, coaxial

(non-ODS)

non-moving metal parts not

connectors, or receptacles.

requiring a lubricated surface;

Do not use around oxygen,

exterior surface of electrical

oxygen fittings, or oxygen

connectors.

regulators, since fire or explosion

may result.

Not intended for use on exterior

Lubricants, Corrosion

Water displacing lubricant

Apply by spraying an even,

surfaces of avionic equipment.

Preventative Compound,

and corrosion preventative,

thin film to the surface. Two

Water Displacing,

for use on in-service

coats shall be applied. Allow

Deposits a thin film which must

Synthetic, with added

equipment and parts at

to dry between coats. The

be removed for proper function of

corrosion inhibitor

temperatures from -65 F to

combined thickness of the

contact points and other

+400 F

two coats after drying shall be

electromechanical devices where

MIL-L-87177

1.2 to 1.5 mils.

no slipping or wiping action is

Type I Grade B

involved.

Application by wiping is not

(Air Force only)

recommended.

Do not use around oxygen,

or

oxygen fittings, or oxygen

Can be removed with

Type II Grade B

regulators since fire or explosion

cleaning solvent.

(Air Force only)

may result.

Reapplication of compound is

necessary after solvent

cleaning or where coating has

been damaged by abrasion.