3-8. INSPECTION

3-9. TESTING

TM 10-8400-203-23

The inspection or quality control element is responsible for determining compliance with repair instructions and

requirements for classification. In-process inspections will be performed for quality of workmanship and correct

application of repair procedures. The completed item will be inspected for serviceable appearance and

condition to insure against return of a sub-standard product to supply channels.

a. Vinyl Casing with Ballistic Insert. Test for water absorption prior to incorporation of the vinyl casing with

ballistic insert into the outer shell. It shall be tested for water absorption to check for efficiency of heat

sealing and for possible damage during processing. Divide units into lots of 25 or less of completed vinyl

casings with ballistic insert. Select one of the units from the twenty-five and weigh accurately to the

nearest 1 ounce (28.35 g). Record this weight. The assembly shall then be totally immersed in water 11 -to

7-inches (27.94 to 17.78 cm) deep and temperature of 70 ± 10°F (21.1 ± 5.5°C) for 30 minutes. The test

assembly shall not be folded unless material such as netting is interlaid between folds which will permit

free entry of water to all surfaces of the specimen. Upon removal at the end of the thirty minute immersion

period, hang the assembly on a line or hanger and allow to drain for approximately 10 minutes. Wipe or

blot dry any visable drops of water on the outside of the envelope and allow to dry another twenty minutes.

At the end of 1/2 hour reweigh the assembly. If the weight is more than 1 percent over that of the original

weight, leakage is indicated. If leakage is indicated, the item should be returned for the application of a

new vinyl casing and all items in the lot of twenty-five should be tested and treated as outlined above.

NOTE

In view of the possible rejection of complete vests in the final test for water

leakage of completed items which do not have new vinyl casings, it is

suggested that these vests be checked 100 percent for water leakage due to

the inability to visibly examine for possible physical damage that could

occur in the translucent casing material.

b. Complete Vest.

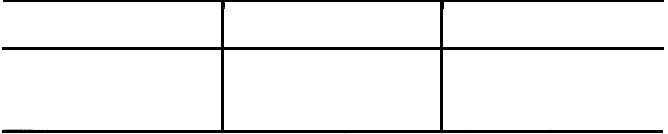

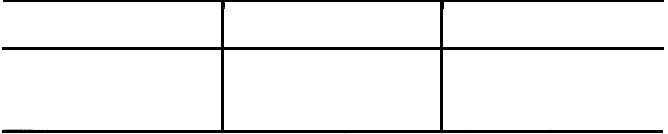

(1) Dry weight tests. All vests (100 percent inspection) being returned to supply channels should be

compared against the following weights for the applicable size and stock number.

I

I

MAXIMUM WEIGHT

NSN

SIZE

OUNCES

8470-00-122-1299

Small

143

8470-00-122-1300

Medium

154

8470-00-122-1301

Large

166

8470-00-122-1302

X-Large

181

3-13