Steel straps may be placed around the sides or over the top

(3) Corner or gate protection must be provided to

and under the load. Since the lading is permitted to move, it

prevent damage to the lading due to pressure of the steel

is important that the car selected for loading has smooth

straps. See figure 40 for corner protection.

floors and sides and is free from projections on which the

(4) The floating load method is adaptable to many

lading may snag. Metals straps may be run horizontally or

commodities, such as crated articles and commodities in

diagonally around the load, as shown in figure 40. In figure

barrels. The principle involved consists of tying the lading into

two compact units with spaces in the doorway area and at

under the unit. Proper protection must be provided at corners

each end of the car, which allow the load to move, thereby

reducing shocks to the lading.

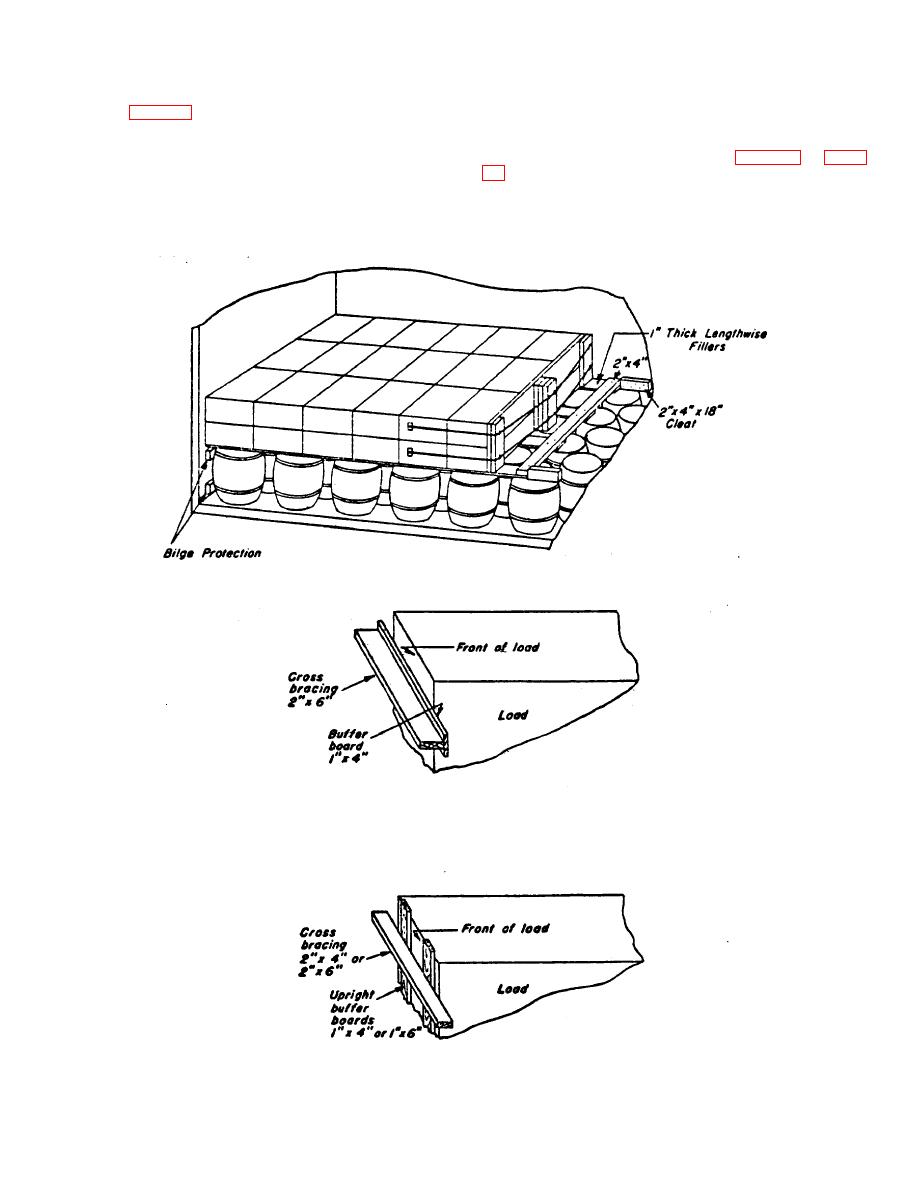

Figure 13. Fillers between layers. Rigidly braced load.

Figure 14. Cross bracing.

11