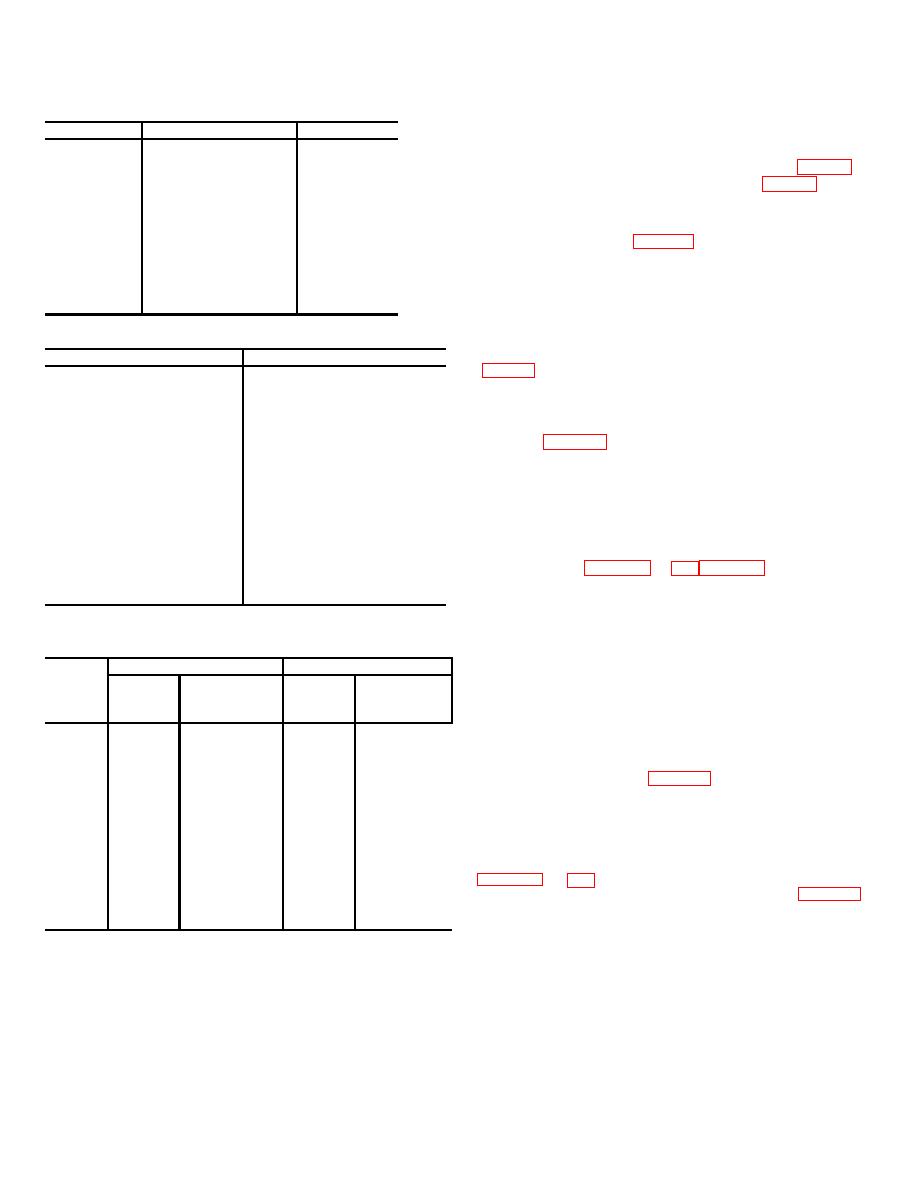

Table 2. Species of Wood Most Commonly Used

For Bracing

(4) In order to reinforce cross car bracing,

Soft woods

Medium woods

Hard woods

diagonal braces extending from the cross brace to the car

Cedar

Douglas Fir

Ash

walls are used to supplement the strength of the cross brace.

Chestnut

Hemlock

Beech

This forms what is known as a K brace as shown in figure 5.

Cottonwood

Maple

Elm

Another adaptation of the K brace is shown in figure 8. In this

Fir, Alpine

Larch

Hickory

example, a single K brace reinforces two cross braces.

Fir, Balsam

Pine

(Northern

Maple (Hard)

(5) The reinforcement of cross car bracing to car

Carolina)

floors can be provided by the use of diagonal bracing to the

car floor as shown in figure 9. The bracing must not be

Fir, White

Pine (Southern Yellow)

Oak

applied at an angle greater than 45 degrees with the car floor.

Pine, Jack

Ash

It is desirable that the cross brace be positioned at a point

Pine, White

approximately one-third down from the top of the load. Table

Spruce

6 shows the minimum length of diagonal braces in relation to

Poplar

height of cross brace above car floor.

(6) Knee braces should be used to prevent

Table 3. Soft and Medium Woods (Standard Sizes)

dislodgment or bowing of floor diagonals and should be

applied at right angles to the floor diagonals, as shown in

Medium woods (in.)

Soft woods (in.)

Size 3/8 x 1 (Lath)

Size 3/8 x 1 (Lath)

(7) Top bracing will be found desirable in many

Size x 4

Size 3/4 x 4

instances to prevent upward movement of a load. The

Size 1 x 2

Size 1/4 x 2

security of this type of bracing is dependent upon the proper

Size 1 x 3

Size 1/4 x 3

application of pocket cleats. Two methods of top bracing are

Size 1 x 4

Size 1/4 x 4

shown in figure 10. Diagonal reinforcement is used for heavy

Size 1 x 6

Size 1/4 x6

loads. However, the top ends of these diagonals should never

be placed at the intersection of the roof and side walls of the

Size 2 x 2

Size 2 x 2

car, but should be backed up with cleats and the diagonal

Size 2 x 3

Size 2 x 3

braces.

Size 2 x 4

Size 2 x 4

(8) Bracing used to prevent top-heavy articles

Size 2 x 6

Size 2 x 6

from falling or tipping over in transit should be placed at a

Size 3 x 4

Size 4 x 4

point approximately opposite the upper third of the article.

Size 4 x 4

Size 4 x 5

This type of bracing' is commonly referred to as collar bracing

Size 4 x 6

Size 5 x 6

and is shown in figures 11 and 12. Figure 11 shows two types

Size 6 x 6

Size 6 x 7

of machines, A and B. Type A is of solid cast iron base

construction and should be blocked against the skid members

Size 6 x 8

Size 7 x 8

as shown.

Type B, which is a leg-type construction, must not be blocked

Table 4. Cement-Coated Nails and Round Wire

crosswise against the ends of the skid members.

Spikes

(9) When commodities in containers are loaded in

Cement-coated nails

Round wire spikes

more than one layer, filler boards should be used to provide

an even base for the containers in the upper layers. Fillers

Length

Gauge No.

Length

Gauge No.

must be of sound material at least 1-inch thick to carry the

(in.)

(in.)

or size (in.)

weight of the load, and must be placed lengthwise in the car.

Size

To hold these fillers securely in place, a crosswise board of 2-

10d*

2 7/8

11

3

6

inch x 4-inch material should be securely nailed to each

12d

3 1/8

10

3 1/4

6

lengthwise filler board. When the load is rigidly braced, this

16d

3 1/4

9

3 1/2

5

unit can then be held in position by means of cleats affixed to

the cars walls, as shown in figure 13.

20d

3 3/4

7

4

4

(10) Location of the inside blocking should be

30d

4 1/4

6

4 1/2

3

marked on the outside of the container in order that the car

40d

4 3/4

5

5

2

loader can determine where to apply blocking.

50d

5 1/4

4

5 1/2

1

(11) Incomplete layers in shipments should be

60d

5 3/4

3

6

1

avoided whenever possible.

However, when incomplete

7 in.

7

5/16 in.

layers have to be loaded, crosswise bracing as shown in

8 in.

8

3/8 in.

9 in.

9

3/8 in.

secured to car walls with pocket cleats, as shown in figure 15.

10 in.

10

3/8 in.

12 in.

12

3/8 in.

*d-Penny

7