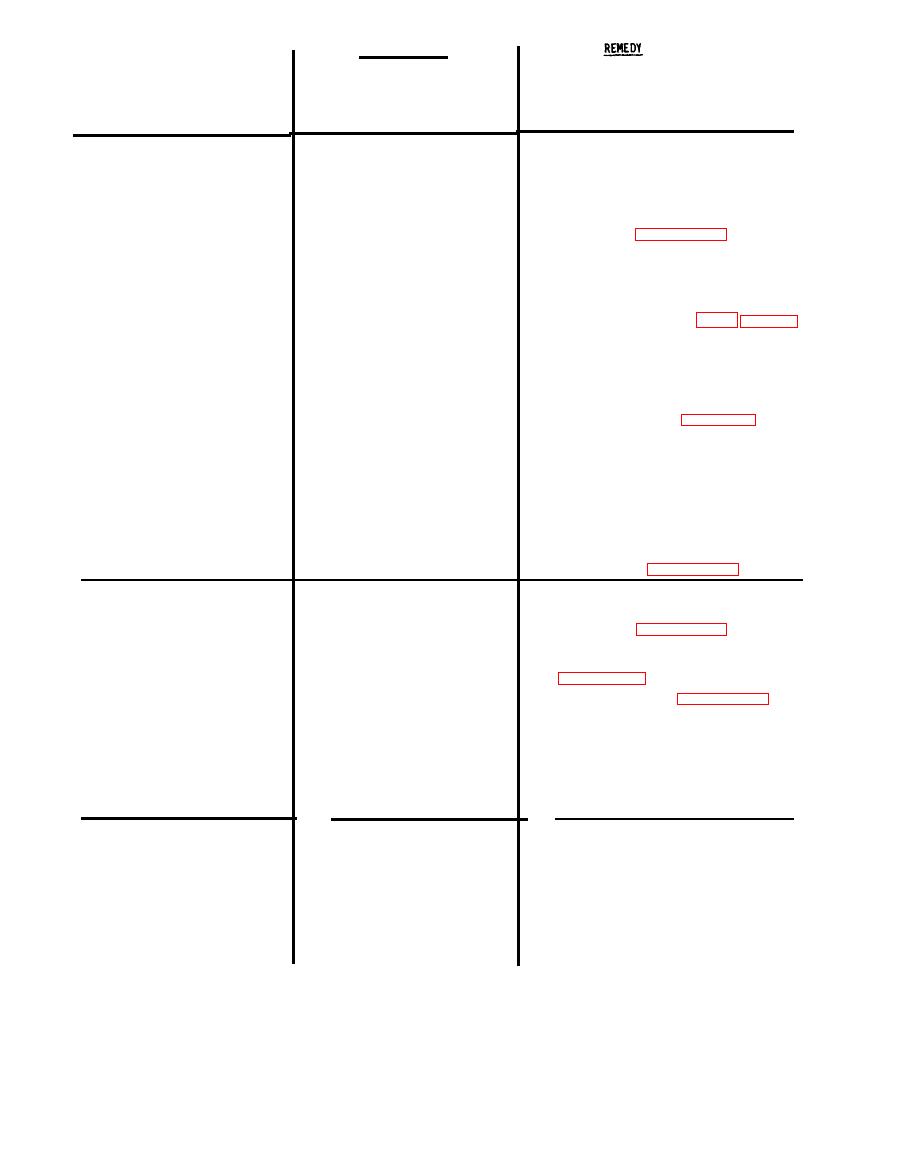

PROBABLE CAUSE

PROBLEM

(continued)

a.

Remove restriction or replace.

a. Restriction in steam hose,

Excessive pressure on

10.4

Make sure gun valve is fully opened.

gun, nozzle or gun `on & off'

steam pressure gauge when

valve partially open.

pump is ON, burner OFF.

Open valves.

a. Burner filter valve turned off

10.5 Burner will not light.

a.

b.

Check steam gun, nozzle and steam

b. Restriction causing back pres-

hose for restriction. Remove and

sure to actuate Hydro/Fuel

clean, Open gun valve.

Safety Modulator to "off" posi-

tion. Gun valve closed.

c. Hydro/Fuel Safety Modulator

Readjust per paragraph 9.1.

c.

not adjusted properly.

d.

d. Burner nozzle dirty or re-

Clean and/or replace nozzle. Clean

nozzle with air pressure only.

stricted,

e.

e. Electrodes cracked or out of

If electrode is cracked, replace.

alignment.

f.

f. Cad-Cell sooted or mis-

Clean or replace, check alignment.

aligned.

Replace

g. Ignition transformer open or

g.

shorted.

h.

Depress reset button (see para-

Safety Control `Open!

h.

graph 9,5)

Check fuel pump for proper opera-

Fuel pump inoperative.

j.

j.

tion. Repair as required.

k.

k.

Motor thermal overload open.

Depress reset button on burner

motor.

l.

Water in fuel tank.

Remove filter bowl and check. Drain

l.

if necessary.

m.

m.

Excessive air adjustment.

Adjust air per paragraph 9.7.

10.6

a.

Unit will not heat

a.

Dirty burner nozzle or

Clean and/or replace with nozzle

(4.0 x 80 PLP-Monarch)

properly.

wrong size.

Hydro/Fuel Safety Modulator

Readjust per paragraph 9.1.

b.

b.

not adjusted properly.

Fuel pump pressure too low.

Readjust fuel pump pressure per

c.

c.

d.

Improper fuel/air mixture.

d.

Adjust air gate per paragraph 9.7.

Back pressure in coil.

e.

Descale if back pressure exceeds

e.

30-40 PSI .

f.

Restriction in combustion

f.

Clean as required.

chamber or vent stack.

Improper or contaminated

Clean or replace fuel to proper

g.

g.

fuel.

specification,

10.7

Lack of soap at steam gun.

a.

Soap solution tank empty.

a.

Recharge tank.

b. Soap metering valve closed

b.

Open valve, remove restriction.

or restricted.

c.

Soap solution weak.

c.

Add more soap concentrate when

recharging soap tank.

d.

Soap solution line to pump

d.

Clean, repair or replace tubing.

clogged, restricted or

kinked.

-18-