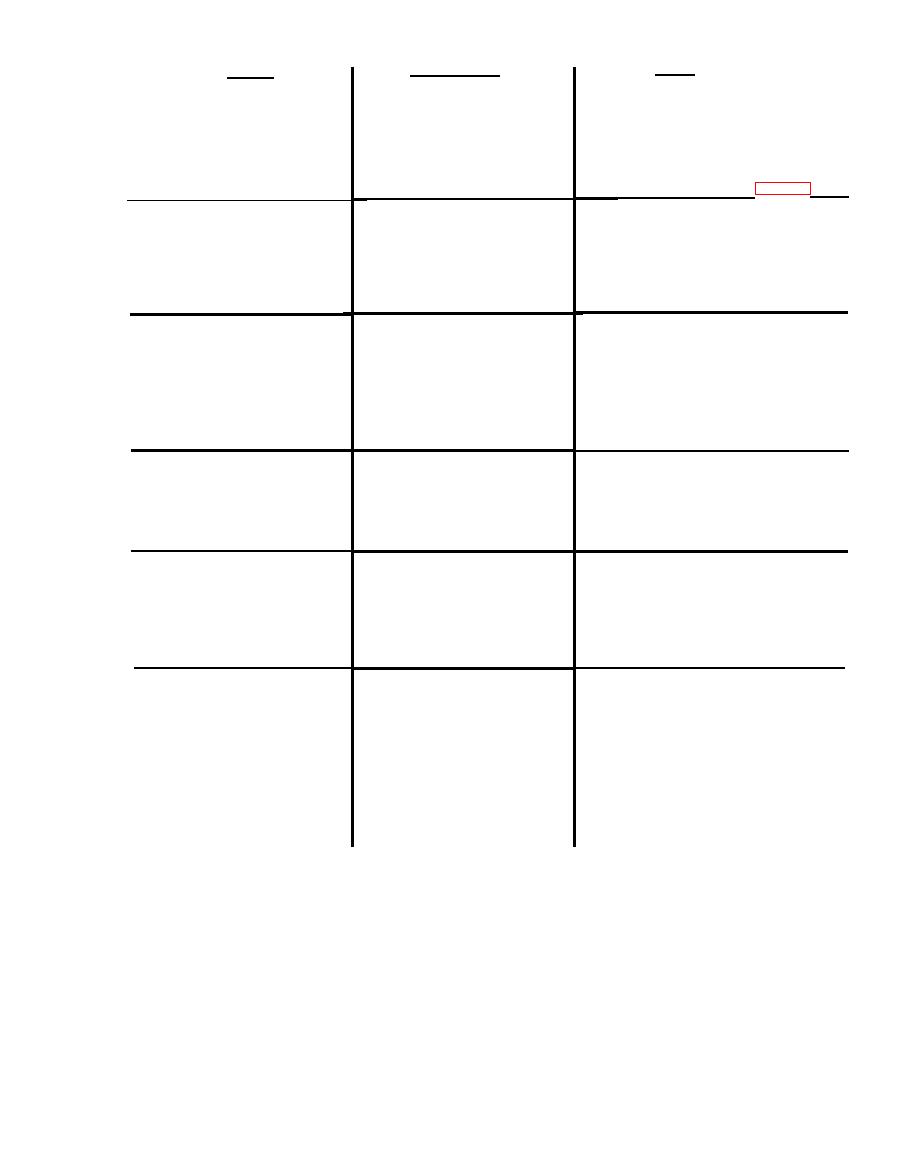

(continued)

REMEDY

PROBABLE CAUSE

PROBLEM

a(1)

a.

Air dome full of water.

Drain air dome every four (4)

10.8 Coil hammering or pounding.

hours of continuous use.

(2)

Leak in air dome. Repair or

replace.

b.

Restriction in water system.

Clean steam gun, nozzle or hose.

b(1)

(2)

If coil back pressure exceeds 30-

40 PSI, descale. (See page 11.)

10.9

Pressure bypass valve

a. Back pressure in coil.

Descale coil if back pressure

a.

opens.

exceeds 30-40 PSI.

b(l) Remove restriction.

b.

Restriction in steam hose,

gun or nozzle.

(2) Open blowdown valve.

c. Restriction in safety relief

c.

Clean or replace valve.

valve.

Air dome full of water.

10.10 Water pump hammering or

a.

a.

Drain air dome.

pounding.

Restriction in steam hose,

b.

Remove restriction.

b.

gun or nozzle.

Tighten belt.

Pump v-belt loose.

c.

c.

Worn parts in pump.

d.

Replace as required.

d.

Replace as required.

e.

e.

Weak check valve springs.

a.

Check all valves, fittings, hose

10.11 Burner cycles on and off

Leaks in water pressure

a.

clamps for leaks. Repair or re-

system.

steam gun closed, pump on.

place as required.

b.

Repair or replace.

b.

Leak in heater coil.

c. By-pass valve leaking.

c.

Repair or replace.

a. Restriction in steam hose,

a.

Remove restriction.

10.12 Burner will not start when

steam gun `ON-OFF' valve is

gun or nozzle.

open, pump and burner ON.

Flow switch malfunctioning.

b.

Clean or replace.

b.

c (1) Repair, tighten connections or

c. Shorts, opens or loose con-

nections in electrical

replace wire.

wiring.

(2) Check overtemperature switch.

Repair or replace.

a.

Cracked electrode insulation.

a.

10.13 Burner will not stay lit.

Clean Cad-Cell, Check alignment.

b.

Cad-Cell dirty or misaligned.

b.

Remove restriction or descale.

c.

Excessive back pressure in

c.

hose or gun causing Hydro/

Fuel Safety Modulator to

shut off fuel to burner.

Drain tank and fill with clean fuel.

d.

Dirty Fuel.

d.

Engage transformer contacts with

Poor transformer contact.

e.

e.

electrode buss bar.