01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

containing ions (such as seawater). Stainless steels

are most susceptible to pitting damage, although

aluminum, magnesium, and copper are often attacked

(see Figure 3-10).

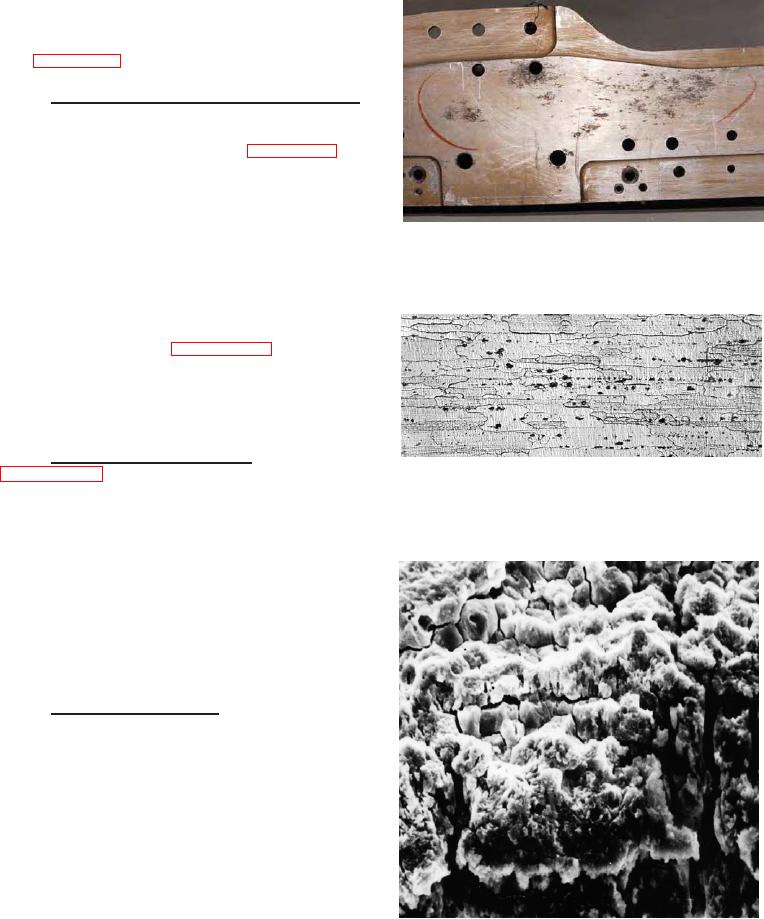

3-9.4. I N T E R G R A N U L A R

CORROSION.

Intergranular corrosion is an attack on the grain

boundaries of the metal. A highly magnified cross

section of any commercial alloy (see Figures 3-11 and

3-12) shows the granular structure of the metal. It

consists of quantities of individual grains, each having

a clearly defined boundary, which chemically differs

from the metal within the grain. Frequently the grain

Figure 3-10. Pitting of an Aluminum Wing Assembly

boundaries are anodic (tend to corrode more easily) to

the metal within the grain. When an electrolyte is

present, rapid selective corrosion of the grain

boundaries occurs. High strength aluminum alloys,

which depend on precipitated phases of alloying

elements for strength, are particularly susceptible to

intergranular attack. Figure 3-13 shows how

intergranular corrosion progresses in 7075-T6

aluminum alloy adjacent to steel fasteners. In this

example, the grain boundaries are anodic to both the

metal grain and the steel fastener.

3-9.5. EXFOLIATION CORROSION. Exfoliation (see

Figure 3-11. Cross-Section of 7075-T6 Aluminum Alloy

Figures 3-14 and 3-15) is an advanced form of

intergranular corrosion where the surface grains of a

metal are lifted up by the force of expanding corrosion

products occurring at the grain boundaries. The lifting

up or swelling is visible evidence of exfoliation corrosion.

Exfoliation occurs on extruded, rolled, wrought, and

forged high strength aluminum and magnesium parts.

This type of corrosion most often occurs on extruded

sections of metal and is found primarily in aluminum

sheet around steel fasteners. Its prevention involves

separating the aluminum and steel by a barrier, such as

zinc-chromate primer or sealant.

3-9.6. CREVICE CORROSION. Crevice corrosion is

one of the most familiar types of corrosion. Field

experience shows that this type of corrosion may occur

in any crevice where a stagnant solution has pooled.

Crevices are usually located at gasket surfaces, lap

joints, and under bolt or rivet heads. Crevice corrosion

occurs because the environment of the local area is

very different from the larger environment. As a result,

the metal surfaces, even though they may be the same

metal, have different activities, and corrosion occurs

inside the crevice. This kind of corrosion can also occur

when a surface is covered by a foreign material. Methods

to minimize crevice corrosion include closing the crevice

Figure 3-12. Scanning Electron Micrograph of a

Corroding Aluminum Surface