01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

No Contact

Between

Unbroken

Electrolyte &

Paint Film

Anode &

Electrolyte

Cathode

(Fresh or Sea Water,

Acids, Gases)

Electrolyte

(Continuous Liquid Path)

Anodic

Cathodic

Area

Area

Cathodic

Anodic

Area

Area

Ele

ctron Flow

Metal

Metal

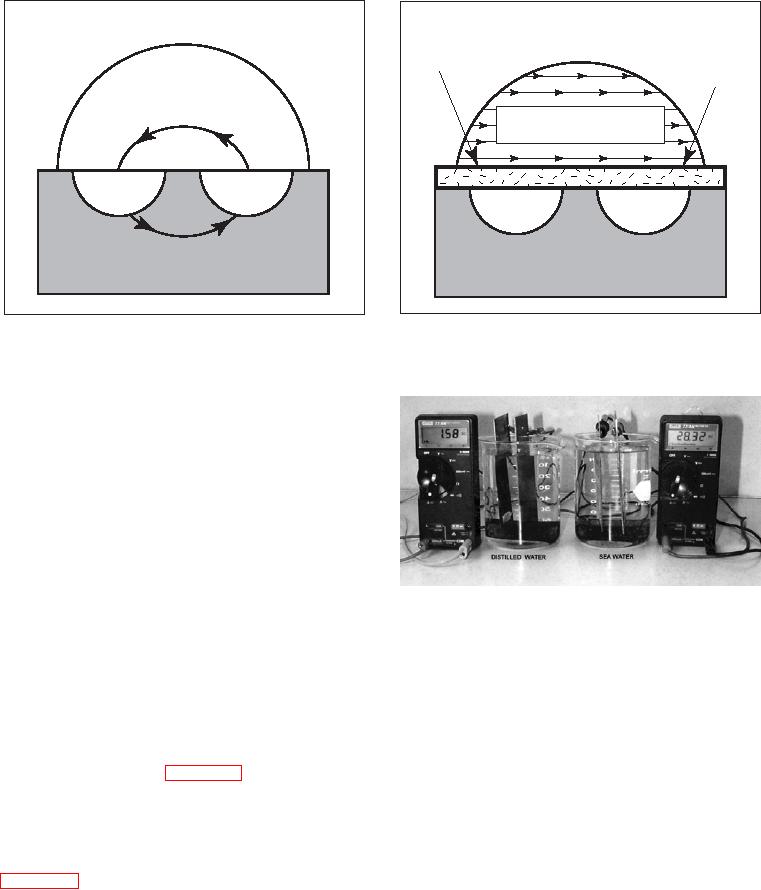

Figure 3-2. Elimination of Corrosion by Application

Figure 3-1. Simplified Corrosion Cell

of an Organic Film to a Metal Surface

a. A metal which has a tendency to corrode must

be present (the corroding metal is called the anode);

b. A dissimilar conductive material (the cathode),

which has less tendency to corrode than the anode,

must be present (a dissimilar metal may be a different

metal, a protected part of the same metal, or conductive

plastic);

c. A conductive liquid (electrolyte) must connect the

anode and cathode (so that ions can carry electric

current between them); and

Figure 3-3. Effect of Sea Water on

d. Electrical contact between the anode and cathode

Galvanic Corrosion

(usually in the form of metal-to-metal contact) must

exist so that electrons can move between the anode

corrosion begins on an inside surface of a component

and the cathode.

(for example, the inner wall of a metal tube), it may go

undetected until perforation occurs.

3-6.2. The elimination of any one of the four conditions

will slow or stop corrosion. For example, a paint film on

3-7.1. When corrosion products form, they often

a metal surface will prevent the electrolyte from

precipitate onto the corroding surface as a powdery

connecting the anode and cathode, thereby stopping

deposit. This film of corrosion products may reduce the

the electric current (see Figure 3-2). A change in the

rate of corrosion, if the film acts like a barrier to

electrolyte can also affect the rate of corrosion. Two

electrolytes. Some metals (such as stainless steel and

connected dissimilar metal parts placed in distilled

titanium), under the right conditions, produce corrosion

water corrode very slowly due to a lack of ions in solution

products that are so tightly bound to the corroding metal

to conduct the electric current; in sea water the corrosion

that they form an invisible oxide film (called a passive

reaction is accelerated by a factor of 1000 or more (see

film) which prevents further corrosion. However, when

the film of corrosion products is loose and porous (such

as those of aluminum and magnesium), an electrolyte

3-7. DEVELOPMENT OF CORROSION. All corrosive

can easily penetrate and continue the corrosion process,

attack begins on the surface of the metal. If allowed to

producing more extensive damage than surface

progress, corrosion can penetrate into the metal. If

appearance would indicate.