TM 10-3510-208-12

TS 10-3510-208-12/4-51 (Sheet 3 of 3)

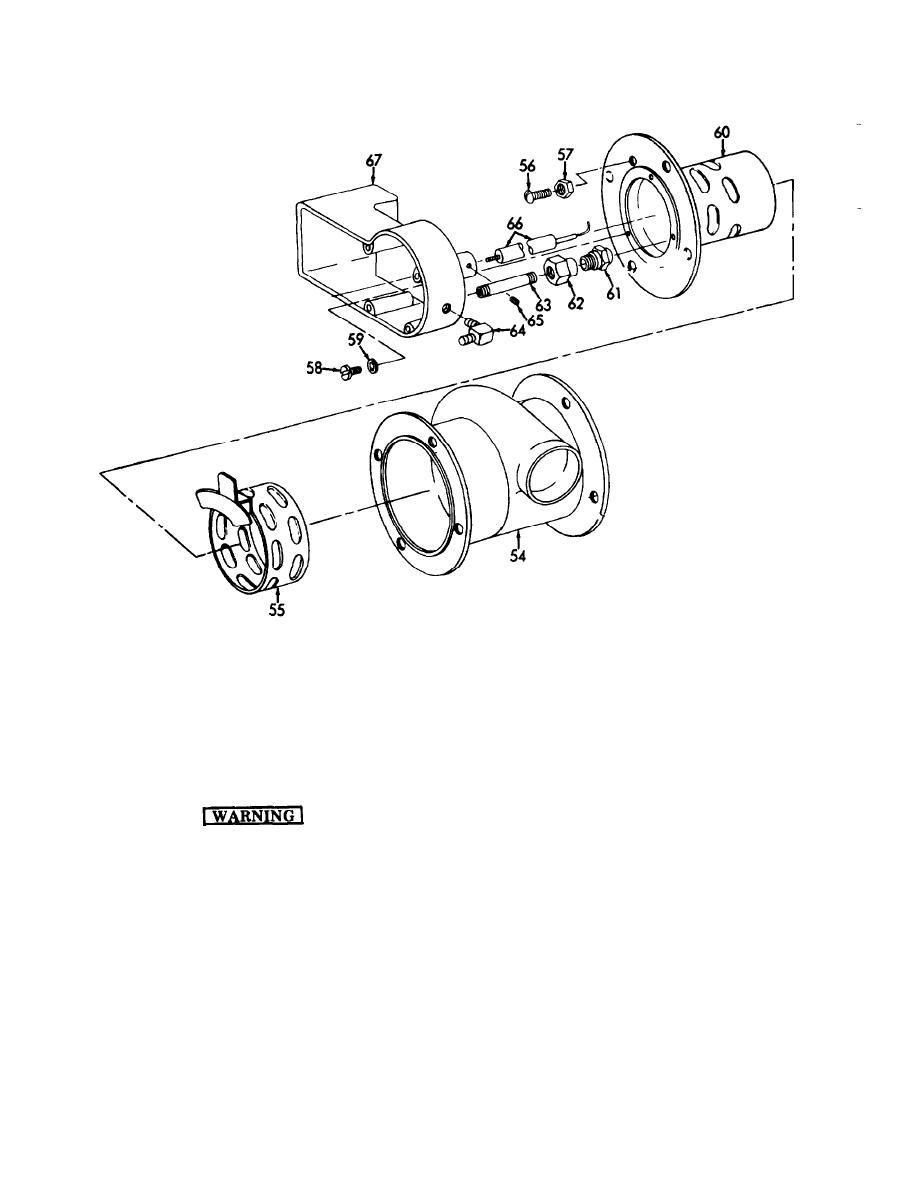

63. Nipple

59. Lockwasher

54. Chamber

64. Elbow

60. Nozzle

55. Shutter

65. Setscrew

61. Nozzle

56. Screw

66. Electrodes

62. Adapter

57. Nut

67. Base

58. Screw

Figure 4-51. Tumbler burner assembly, disassembly and reassembly (sheet 3 of 3).

(1) Clean the exterior surface and glass of the

c. Cleaning.

pressure gage in a mild soap and water solution.

(2) Clean all electrical parts with dry com-

Clean all parts in a well-ventilated area.

pressed air and a clean cloth.

Avoid inhalation of solvent fumes and

(3) Clean hoses and cables using a clean cloth.

prolonged exposure of skin to cleaning

(4) Clean remaining parts using solvent, Fed.

solvent. Wash exposed skin thoroughly.

Spec. P-D-680, and dry thoroughly.

Dry cleaning solvent (Fed. Spec. P-D-680)

d. Inspection.

used to clean parts is potentially dangerous

(1) Inspect all parts of the burner assembly

to personnel and property. Do not use near

for cracks, dents, chips, nicks, deep scores, and

open flame or excessive heat. Flash point

other damage.

of solvent is 100 to 138F. (38 to 59C.).

(2) Inspect all hardware for thread damage.

Do not use compressed air for cleaning

e. Repair. Unless damage is extremely minor

purposes except where reduced to less than

and can be repaired, replacement is recommended

30 psi and then only with effective chip

for all damaged items of the burner assembly.

guarding and personal protective equip-

f. Assembly.

ment.

4-66