TM 10-3510-209-24

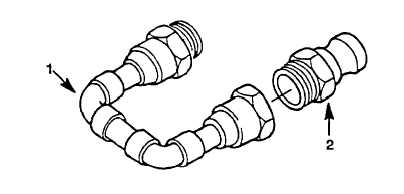

3-15. EXTRACTOR PIPING

This task covers:

Repair

INITIAL SETUP

Materials/Parts

Equipment Condition

Solder (App C, Item 9)

Extractor piping removed (Para 2-31.2)

Flux (App C, Item 25)

Antiseize Compound (App C, Item 26)

General Safety Instructions

Tools

WARNING

General Mechanics Tool Kit (App B, Item 1)

Chemical Agent Resistance Coating (CARC)

Automotive Vehicle Shop Equipment

produces toxic fumes when flame is applied. It is

(App B, Item 6)

necessary to remove CARC in area where flame is to

be applied.

REPAIR

1.

Copper fittings(s).

Remove damaged sections of copper tubing on extractor piping (1) using torch. Refer to

TM 10-3510-209-24P for breakdown of copper tubing.

2.

Threaded coupling.

Remove damaged coupling (2). Before installing coupling, apply antiseize compound to male

threads.

3.

Install extractor piping (1) (Para 2-31.2).

Pages 3-57 and 3-58 deleted

Change 4 3-55/(3-56 blank)