TM 55-1615-226-40

pit. Do not remove more

material than necessary to

effect repair as described.

Do not use grinding wheel

for repair.

Polish out corrosion dam-

age with fine to medium

grade abrasive cloth, (item

2, table 1-2) or fine India

stone and final polish to a

scratch-free finish with

crocus cloth (item 3, table

1-2).

Cadmium plating re-

moved by repair should be

reapplied by brush plating

(item 4, table l-2). Repair

areas on

aluminum

anodized surface with

brush alodine (item 9, table

1-2).

m. Repair corrosion damage to sleeve as

follows

NOTE

Damage in any one area

must not exceed 0.25

square inch in area or 0.75

inch in any one length. The

area wherein the repair is

blended into the surround-

ing area is not included in

these limits.

(1) Polish out corrosion damage not

exceeding 0.005 inch in depth to the flat surfaces

surrounding the I. MO-inch diameter holes and the

inside and outside of the 4.080-inch OD cylindrical

surfaces. Damage shall not exceed 0.010-inch depth

after repair.

(2) Corrosion damage shall not exceed

0.017 inch in depth in all areas of the sleeve other

than specified in step m, (1) above. Damage shall not

exceed 0.035 inch in depth after repair.

NOTE

Polish out corrosion dam-

age blending the repair

smoothly into the sur-

rounding surface. Polish

out corrosion damage to

twice the depth of the grit.

Do not remove more mat-

erial than necessary to

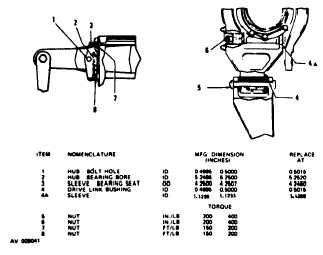

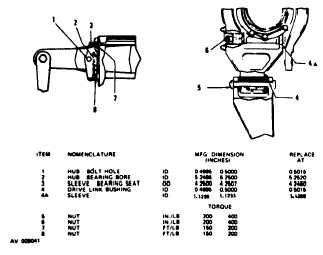

Figure 2-2. Limits Charts - Scissors and Sleeve

Assembly.

effect repair as described.

Do not use grinding wheel.

Polish out corrosion dam-

age with fine to medium

grade abasive cloth (item

2, table 1-2) or fine India

stone, and final polish to a

scratch-free finish with

crocus cloth (item 3, table

1-2).

Cadmium plating re-

moved by repair should be

reapplied by brush cad-

mium plating (item 4,

table 1-2). Repair areas on

aluminum anodized sur-

faces with brush alodine

(item 9, table 1-2).

n. Score msarks on the inside surface of holes

and bushinga may be polished out if the damage is

0.002 inch or less.

2-28. Lubrication.

2-29. Lubricate mating surfaces during reassembly

with oil (item 5, table 1-2). Use compound (item 6,

table 1-2) on mating threads of dissimilar metal.

Repack bearings that do not have lubrication

fittings, before reassembly, with grease (item 7, table

1-2).

2-11