3

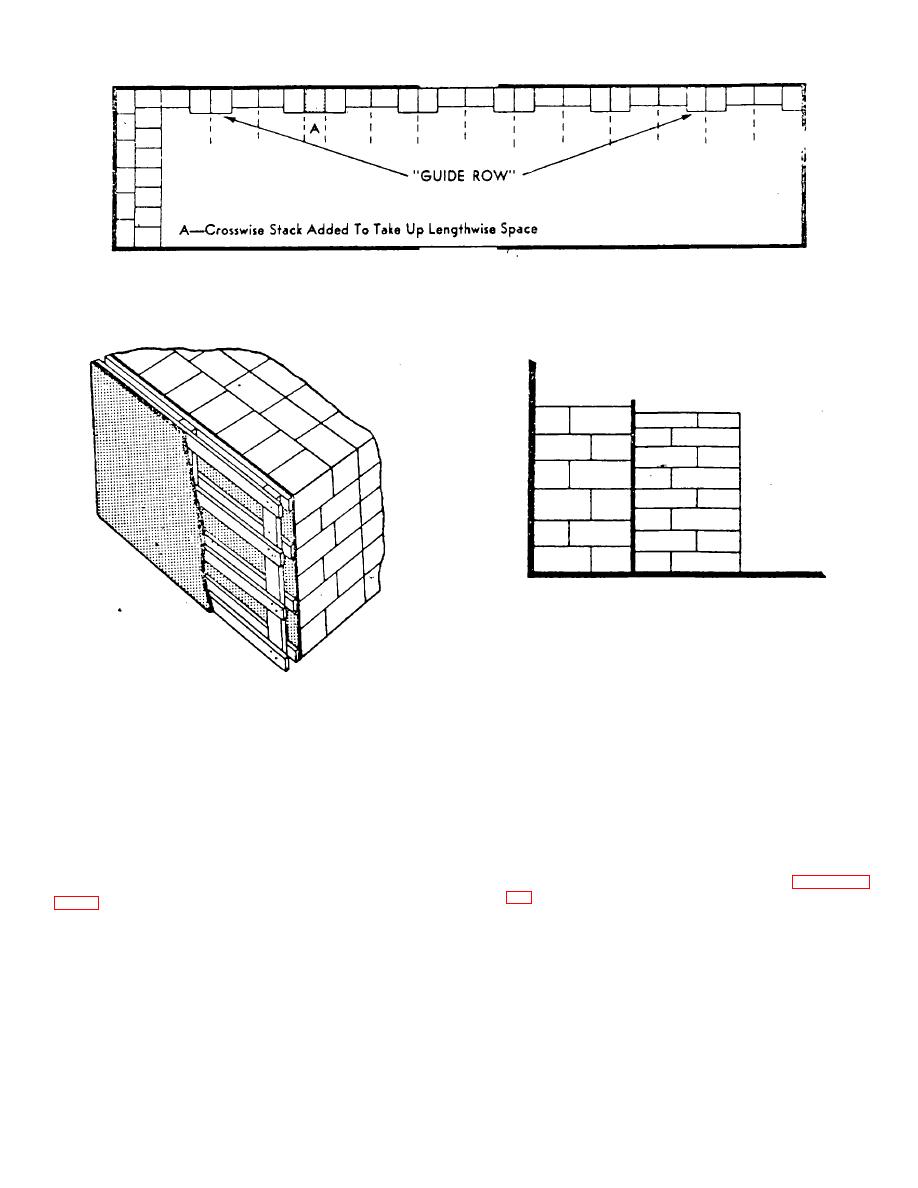

Figure 61. Guide Row.

Figure 63. Divider sheets.

(c) Load machines with overhanging

projections far enough away from car sides, end walls, and

other freight to prevent damage.

(d) Do not load loose parts or other freight

adjacent to machines where a shift is liable to cause damage.

(e) When loading heavy machinery, be

Figure 62. Fiberboard material or bulkheads used

certain there is proper weight distribution in the car.

to fill vacant space.

packaged; and recoopering is accomplished when necessary.

c. Doorway Protection.

(1) Doorway protection must be used when

b. Machinery.

railcars are not equipped with plug (flush) doors and freight

(1) Machinery

presents

special

shipping

loaded in the doorway area of the car is liable to contact

problems, as most units are unique in configuration, size,

doorposts and doors.

construction, weight, and weight distribution.

For safe

(2) When lading is only one layer high, one 2-inch

transport, most machinery must be properly crated, skid

x 4-inch piece of lumber nailed to each doorway threshold will

mounted, or otherwise prepared by the shipper, as explained

usually restrain the load satisfactorily. When lading is in two

and illustrated in AAR Pamphlet No. 21, Rules Regulating the

or more layers, other methods should be used. Figures 72

Preparation and Safe Loading of Machinery in Closed Cars

and 73 depict three types of doorway protection.

7. Loading of Hazardous Materials

(2) Damage to machinery can be prevented by

All shipments in the United States of hazardous materials,

proper preparation of the units for transportation, and by

such as explosives, flammables, acids, corrosive liquids, etc.,

following basic loading and bracing principles; such as-.

must be packaged, blocked, and braced in accordance with

(a) Always load units with skids lengthwise

Mr. R. M. Graziano's Tariff No. 27, or reissues thereof,

of the car.

Hazardous Materials Regulations of the

(b) Never fasten skid runners to the car

floor.

37