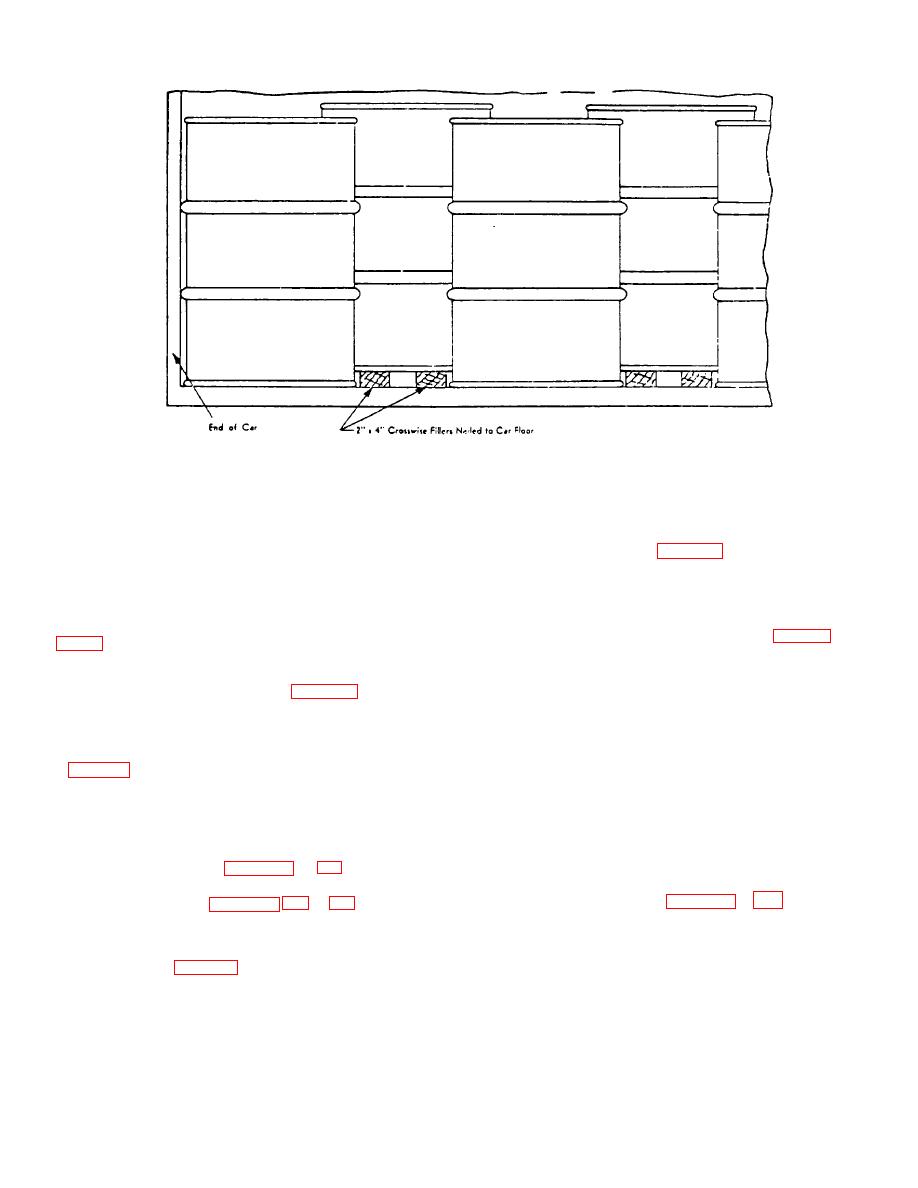

Figure 57. Rigid Braced method of loading metal drums with rolling hoops.

the containers are bonded together into units by reversing

all other odd layers are the same as layer 1, while the even

each layer. It is most important that as the containers are

numbered layers are the same as the second layer.

stowed in the car, they be firmly pressed back into place and

when the doorway is' reached that all open space lengthwise

(b) In pattern B, start the block in the floor

of the car be taken up by appropriate means.

area as shown in pattern A, figure 66. The second layer is the

reverse of the floor layer.

(3) Loading should be planned in advance by

The third layer and all other odd layers are the same as the

running a "Guide Row" the full length of the car along one side

floor layer and all other even layers are the same as the

wall to set up the pattern for the whole load and to determine

second layer.

the amount of lengthwise space required to make a tight load

(c) To start pattern C (fig 67) the

containers are arranged similar to pattern A with the exception

must be filled using fiberboard material or wood bulkheads.

that a pinwheel or chimney is used to take up excess

The face of the wood bulkheads next to containers should be

crosswise space. The pinwheel or chimney is reversed from

covered with fiberboard, as shown in figure 62. The bonded

side to side in alternate layers of the block. The third and all

blocks will not always fill all the lengthwise space in the car.

other odd layers are the same as the floor layer, and the

In such cases some of the containers near the doorway area

fourth and all other even layers are the same as the second

of the Guide Row should be rearranged, placing a stack or

layer.

two crosswise or lengthwise to fill most of the space as shown

in figure 61. Any remaining space should be filled with sheets

(6)

Palletized loads.

of fiberboard or knocked down fiberboard containers.

(4) The load should be divided into sections by

placing sheets of fiberboard between every second or third

(a) Palletizing of packaged goods affords

block. Full sheets of fiberboard, preferably 80 point solid

an efficient means of loading and unloading. In order to

fiberboard, should always be used between blocks of different

obtain such efficiencies, however, it is necessary to utilize

size containers, as shown in figures 63 and 64.

completely both the lengthwise and crosswise space in the

car. This affords the opportunity for maximum load with

(5) There are three basic patterns for bonded

minimum bracing as shown in figures 68 and 69.

block loading, as shown in figures 65, 66, and 67.

(b) To obtain the best load and stack

(a) Start the block by placing the contain-

stability for the units and efficiency in handling operations, the

ers in the floor area crosswise and lengthwise of the car as

guidelines that follow can be of assistance:

shown in pattern A, figure 65. In the second layer of the block

the position of the containers is reversed. The third layer and

34