SB 740-94-8

classification of test failures is provided to differentiate

plied packaging, packing, marking, and preservation

between the test failures to be considered as Critical,

processes. The defects are identified in table C-1. The

wherein one item failing the test would be cause for

end item samples shall be visually inspected for the

immediately suspending the lot from issue and use, and

defects listed in table C-2.

Samples of major

the test failures to be considered as major, wherein

component items packed separately shall be visually

acceptance or rejection of the lot would be Eased on the

inspected for the defects listed in tables C-3, C-4, and

acceptance number of the sampling plan.

C-5. The required samples for testing of visually

acceptable items shall be subjected to the applicable

a. Classification of Defects for Packaging, Packing,

tests described in c below. Tables C-2, C-3, C-4, and C-

Marking, and Preservation

5, in addition to providing classification

of visual

defects,

provide classification of test failures. The

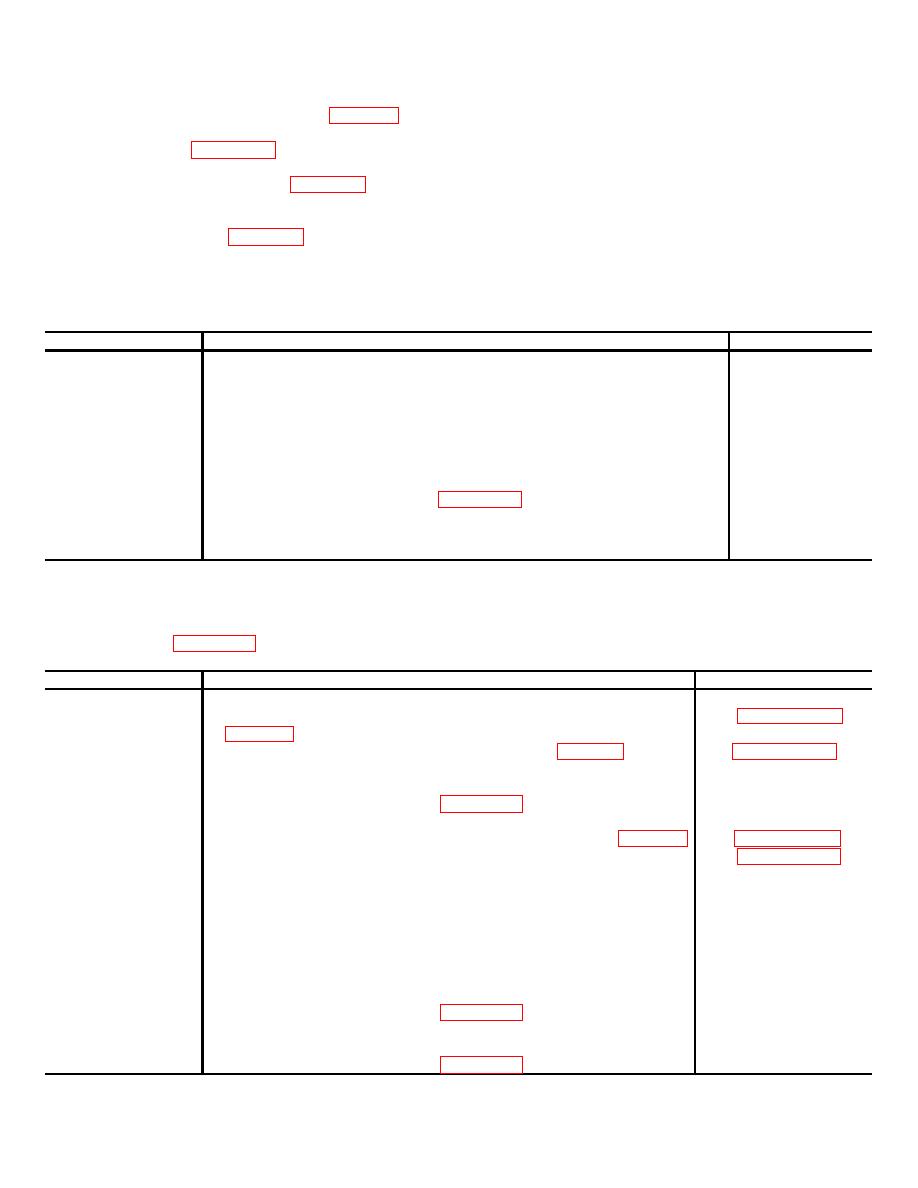

Table C-1. Packaging, Packing, Marking, and Preservation, Disperser, M33A1 NSN 1040-00-148-9824

Category defect No.

Defect

Inspection method

Critical:

None defined.

Major:

101

Shipping or inner containers damaged, deteriorated, or weathered to

Visual

the extent that contents cannot be adequately protected and containers

require replacement.

102

Inner container wet or mildewed.

Visual

103

Loose pack (packing so loose that contents have been broken or are in

Visual

danger of being broken),

Other

Refer to "Quality Defect Codes" in appendix A

Visual

Minor:

201

Slight damage, deterioration, or weathering to outer or inner con-

Visual

b. Classification of Defects for End Items.

Table C-2. Disperser, Riot Control Agent, Portable, 3-Gallon, M33A1 NSN 1040-00-148-9824

NOTE:

Refer to tables C-3, C-4, and C-5 for classification of defects for major components packed

separately.

Category defect No.

Defect

Inspection method

Critical:

1

High pressure tank hydrostatic volumetric test failure (refer to

Test, paragraph C-4c(1)

2

Agent tank hydrostatic pressure test failure (refer to table C-3).

Test paragraph C-4c(2)

3

Pressure tank cracked or dented.

Visual

4

Agent tank cracked or dented.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Major:

101

Gun assembly leakage and functional test failure (refer to table C-5).

Test, paragraph C-4c(3)

102

Disperser assembly leakage and functional test failure.

Test, paragraph C-4c(4)

103

Hydrostatic test date marking missing from tanks.

Visual

104

Component or publication missing (refer to TM 3--1040-262-13).

Visual

105

Connector (coupling, thread, locknut, or cap) damaged, corroded or

Visual/Manual

inoperative.

106

Hose damaged or deteriorated including soft or rust spots or kink caus-

Visual

ing permanent set.

107

Rubber tube (gun groups) cut, split, or deteriorated.

Visual

108

Carrier damaged or deteriorated (frame bent or broken, straps torn).

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

201

Strap buckles rusted.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

C-2