SB 740-94-8

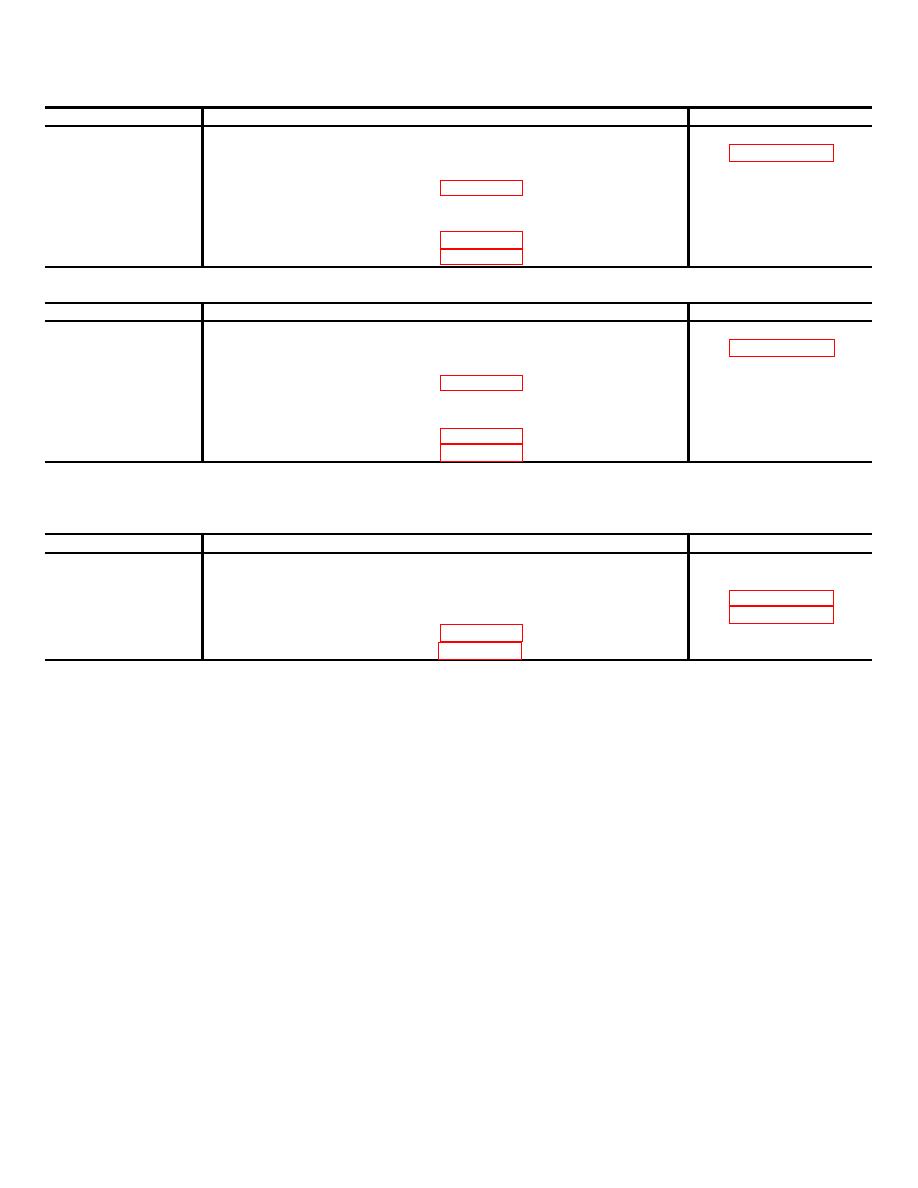

Table C-3. Cylinder, Compressed Gas (Agent) NSN 1040-00-116+0355

Category defect No.

Defect

Inspection method

Critical:

1

Agent tank hydrostatic pressure test failure.

Test, paragraph C-4c(2)

2

Agent tank cracked or dented.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Major:

101

Hydrostatic test date marking missing from agent tanks.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

Table C-4. Cylinder, Compressed Gas (Air), NSN 104-00-198-4924

Category defect No.

Defect

Inspection method

Critical:

1

High pressure tank hydrostatic volumetric test failure.

Test, paragraph C-4c(1)

2

High pressure tank cracked or dented.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Major:

101

Hydrostatic test date marking missing from high pressure tank.

Visual

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A.

Visual

Table C-5. Gun, Portable, Riot Control Agent Disperser, NSN 1040-01-060-8579

NOTE

This gun is listed as Gun, Spray, Chemical in the Army Master Data File.

Category defect No.

Defect

Inspection method

Critical:

None defined.

Major:

101

Gun assembly leakage and functioning test failure.

Test, paragraph C-4c(4)

102

Functioning slow or not positive

Test, paragraph C-4c(4)

Other

Refer to "Quality Defect Codes" in appendix A.

Visual

Minor:

Refer to "Quality Defect Codes" in appendix A

Visual

should be of sufficient strength to

c. Tests.

withstand an impact resulting from a

WARNING

rupture of the test equipment or

Only authorized personnel (those

specimen.

thoroughly trained in the operation

(1) M33A1

disperser,

high

pressure

tank,

of the disperser) are permitted to

hydrostatic volumetric test.

charge, service or function the

disperser.

Personnel shall wear

(a) Requirements.

No leakage shall be

approved eye protective equipment

observed when the high pressure tank is subjected to an

internal hydrostatic pressure of 3500 + 50 pounds per

when conducting tests.

Firmly

square inch gage (psig) for a period of 60 + 10 seconds.

anchor all pressure hoses, test

This test shall be performed by the water jacket, or other

specimens, or other pieces of

suitable method. Permanent volumetric expansion may

equipment

capable

of

being

not exceed 10 percent of the total volumetric expansion

propelled in the event of rupture.

during the tests. If the test. pressure cannot be

Examine test samples and test

maintained, because of test equipment failure, repeat

equipment for foreign matter prior to

the test at a pressure increase of 10 percent, or 100

testing. Isolate the test equipment

psig, whichever is the smaller increase.

and specimens when conducting

(b) Equipment required. A water jacket and a

hydrostatic or functional tests.

regulated pressure source (3600 psig). The pressure

Where possible, locate pressure

gages shall be checked for a minimum accuracy of + I

gages and operating controls a safe

minor scale division. The expansion gage shall be of

distance from the test site. When

such precision as to permit a reading to an accuracy of

conducting a visual examination for

either one percent or 0.1 cubic centimeter.

leakage, a portable shield mounted

on casters may be used. The shield

C-3