01 March 2005

NAVAIR 01-1A-509-1

TM 1-1500-344-23-1

TO 1-1-689-1

2-6.1. TRAINING. Personnel performing maintenance

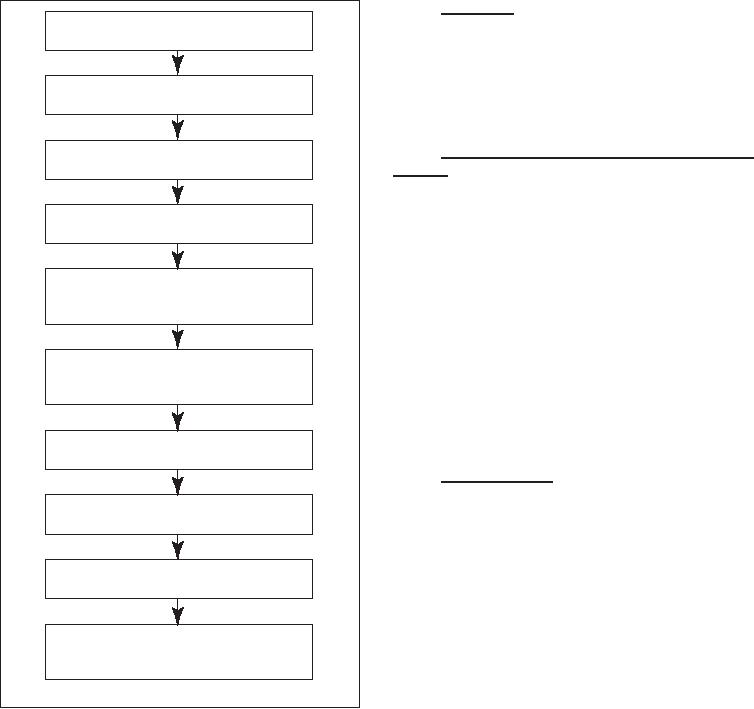

Establish Maintenance Requirements

on aircraft shall be trained in basic corrosion control

for Corrosion Control

skills as established by the parent service organization.

Personnel shall be fully aware of the reasons for the

corrosion control program. Without such training and

Establish Requirements

understanding, further damage or additional problems

to Inspect for Corrosion Damage

may result.

2-6.2. TRAINING AND QUALIFICATION REQUIRE-

Aquire Corrosion Control Equipment

& Consumable Supplies

MENTS. Personnel responsible for corrosion control

maintenance and treatment shall receive the following

training.

Establish Requirements for

Reporting Corrosion Damage

a. Supervisors and corrosion control personnel shall

attend basic corrosion control courses established by

the parent service organization.

Develop & Maintain Maintenance

Instructions Outlining

Corrosion Control Program

b. Cleaning and repair personnel shall be trained in

inspection, identification, cleaning, treatment,

preservation, lubrication, hazardous material handling/

Develop Program to Satisfy Specific

hazardous waste disposal, and proper documentation

Inspection, Cleaning, Treatment,

reporting.

Preservation & Lubrication Requirements

c. Supervisors shall ensure maximum use of in-

service and on-the-job-training.

Develop Cleaning & Corrosion

Training Program

2-6.3. MAINTENANCE. An effective corrosion control

program shall include thorough cleaning, inspection,

Ensure Proper Training of Personnel

preservation, and lubrication, at specified intervals, in

in Corrosion Identification & Control

accordance with Volumes II and III of this manual.

Check for corrosion damage and integrity of protective

finishes during all scheduled and unscheduled

Conduct Required

maintenance. Early detection and repair of corrosion

Corrosion Inspections

will limit further damage. When corrosion is discovered,

treat corrosion as prescribed in Volumes II and III as

Ensure Cleaning, Treatment,

soon as possible and use only approved materials,

Preservation, & Lubrication

equipment, and techniques. Only affected areas shall

are Completed

be repaired. All maintenance personnel shall report

corrosion promptly, in accordance with directives

established by the parent service organization.

Figure 2-2. Basic Maintenance Functions

2-7. C O R R O S I O N - R E L A T E D F A I L U R E D A T A

FEEDBACK.

aircraft engine exhausts. Land-based aircraft may be

exposed to industrial gases, salts, rain, mud, and, near

2-7.1. Since corrosion prevention and control for aircraft

salt water, mists containing sea salts. A comprehensive

and avionics is a continuing concern, it is vitally important

corrosion control program shall consist of either a

that corrosion problems are properly reported. Problems

Corrosion Control Work Center or a Corrosion Control

can be corrected and improvements made to prevent

Team with personnel trained in the prevention, early

reoccurrence in future equipment design. Identification

detection, reporting, and repair of corrosion damage.

of the specific causes and extent of corrosion problems

Such a program requires a dedicated effort by all

is essential. Improved equipment performance and

maintenance personnel to prevent corrosion before it

maintenance assistance (personnel, equipment,

starts. These efforts will improve the operational

materials, and procedures) are dependent on this data.

readiness of equipment and minimize costly repairs.