NAVAIR 01-1A-509-3

01 March 2005

TM 1-1500-344-23-3

TO 1-1-689-3

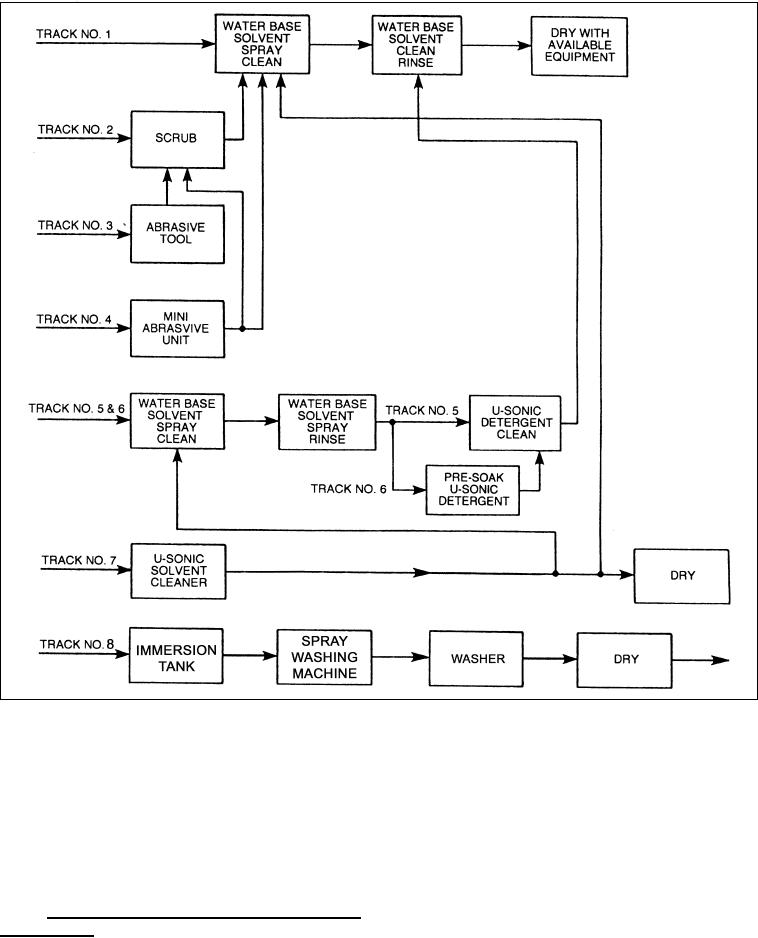

Figure 2-3. Cleaning Track Diagram

corrosion damage. Visual inspection also determines

type of contamination and extent of the damage to

the cleaning method required to remove contaminants

select the correct cleaning track. Experience has shown

or corrosion from tight areas. The aqueous ultrasonic

that most avionic equipment has dirt, dust, or some

and solvent ultrasonic cleaners provide the most

form of corrosion present, and requires cleaning. If

efficient means of cleaning hard to reach areas.

contamination or corrosion is not evident, confirmation

Consideration must also be given to drying that follows

via inspection by an experienced avionic technician is

the cleaning cycle. In some cases, the most efficient

required.

means of cleaning may require extensive drying. This

makes the whole process less efficient.

2-4.5. ACCESSIBILITY TO CONTAMINATION AND

CORROSION. Visual inspection of avionic components

usually indicates the extent of contamination and